To begin with, it is worth deciding on whether you will consider a water or electric floor heating. Water - this is a lot of money at the installation stage, the minimum thickness is 5.5-6 cm, complicated installation and wait almost a month after filling the screed before the start of operation. True, you can lay the tile in two weeks. And to turn on the warm floor is definitely not earlier than a month. But in the heating season, heating costs will be, if more, then slightly.

Types of underfloor heating for tiles, their advantages and disadvantages

Types of underfloor heating for tiles, their advantages and disadvantages

Electric tile heaters are quicker and easier to install. The cost of installing an electric heater under the tile is low. You will need a special tile adhesive (for underfloor heating), a heater and a temperature control and adjustment system. The entire installation and connection of an electric heated floor for one room can take one day. Together with tile laying more is possible. Depends on experience and area.

There is an option for a warm electric floor for tiles, with which the floor height does not increase much. A centimeter, maybe a little more or less. The commissioning period is a couple of days. Until the glue dries. This is if you lay cable mats under the tile. Three or more centimeters the floor level rises, if you make heating from a heating cable. But in this case, the screed should also “mature” for a month. But the cost of equipment for floor heating is less.

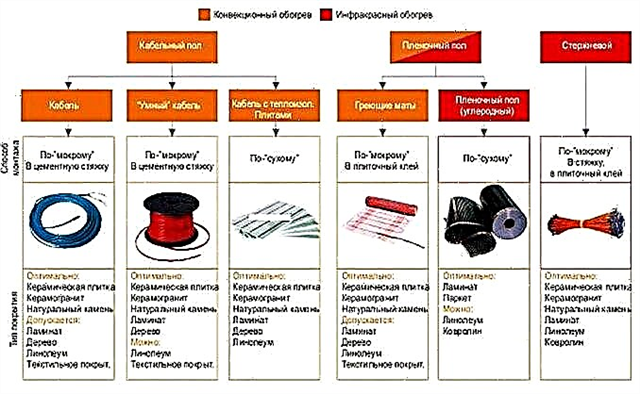

All methods of floor heating

All methods of floor heating

It seems like an electric heated floor looks more attractive. But we must take into account that floor heating with electricity is more expensive. That is, heating costs will increase. How hard to say. Depends on the quality of thermal insulation of the floor and the room as a whole.

In fact, you have to choose whether to invest a lot of money during installation or pay a little each month for heating. Well, you have to take into account the complexity and duration of installation and the timing of commissioning.

Types of heating cables and their properties

There are two types of cables for underfloor heating - resistive and self-regulating. For the manufacture of resistive materials are used that produce heat when current flows. Usually it is an alloy of metals in a polymer heat-resistant shell. Resistive heating cable for underfloor heating can be single-core and two-core. A single-core cable must be connected from two ends, a two-core cable - from only one. This is the main difference between the two.

Cables for underfloor heating are resistive and self-regulating or “smart”

Cables for underfloor heating are resistive and self-regulating or “smart”

And what are the disadvantages of resistive heating cables? The main thing is that when overheated, they can burn out. And they can overheat if something is put on the floor for a long time that worsens the heat removal from this area of the floor. So you have to be careful with this.

Self-regulating cables are named so because when the temperature rises, they automatically cool. In fact, these are not cables, but parallel-connected polymer matrices. The polymer is used with special properties. The higher its temperature, the higher the resistance.

The difference between connecting single-core and two-core heating cables

The difference between connecting single-core and two-core heating cables

An increase in resistance leads to a decrease in current, and this in turn leads to a decrease in temperature. Thus, the degree of heating on the segment of such a cable is regulated. It seems like an ideal option. Except that it is not very reliable and often burns out. Therefore, despite the shortcomings, most often under the tile is laid a resistive cable or mats from it. They are cheaper and more durable.

How to lay a heating cable and what is a cable mat

The heating cable is usually laid with a snake on the surface of the floor, not occupied by furniture. The cable laying step is determined by the required heating power.When mounting the hinges are attached to special clamps. That is, the process of laying out and fixing takes time. And the cable is poured with a screed of 3 cm. That is, if you want to lay a heating cable under the tile on the floor, you will need to fill in the screed. And wait 28 days before the first inclusion. It is not possible to lay the heating cable immediately under the tile. He does not provide for this.

Underfloor heating cable under the tile. The heater is rolled into a screed, and then the tile is laid on the screed on tile adhesive

Underfloor heating cable under the tile. The heater is rolled into a screed, and then the tile is laid on the screed on tile adhesive

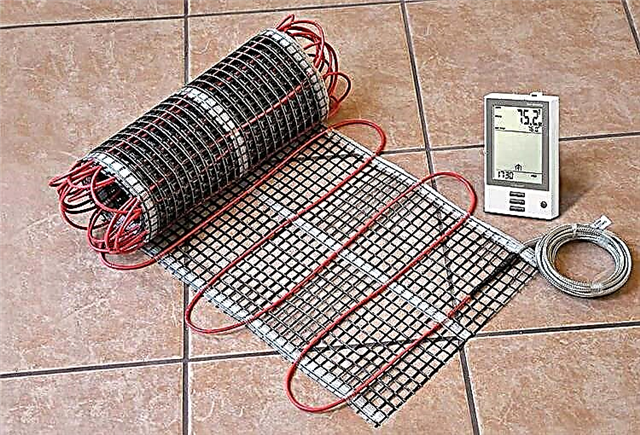

A cable mat is a polymer net onto which a heating cable is glued by a snake. These fragments can be of different lengths and power. And the width is usually 60 cm. So you can choose the size for any room. When laying, the mat is simply rolled out on the floor. And the floor is ready for laying floor tiles.

The easiest to install - cable mat

The easiest to install - cable mat

Tile glue is applied to the mat "under the comb", tiles are immediately laid out on it. No extra layers or work. So under the tile, this type of heater is ideal.

Other types of electric underfloor heating floor tiles

Even under the tiles on the floor, you can lay a film and rod heater. But in this design, they have more disadvantages than advantages.

If you consider all the options for a warm floor, then only infrared film is not suitable for laying under a tile

If you consider all the options for a warm floor, then only infrared film is not suitable for laying under a tile

Should I use an infrared film floor

Film underfloor heating - strips of carbon paste rolled up in film. When laying under a tile, the adhesive is applied to the film, and the film is laid on it. That is, installation as when laying a cable mat. But this heating option is worse in terms of durability. The heater itself is a separator between the base and the adhesive layer. It turns out that the tile lies on a layer of glue and is not connected in any way with the floor under it. And this leads to the fact that over time from vibration, the upper layer is destroyed. A layer of glue, followed by tiles, crack.

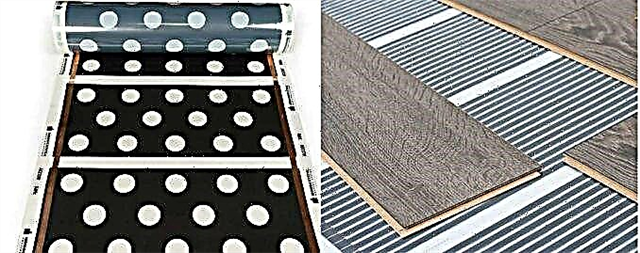

Even a special perforated film is better not to lay under the tile

Even a special perforated film is better not to lay under the tile

Manufacturers in attempts to adapt this material for laying with tiles, make a film with through holes. This option provides some degree of adhesion to the base. But it only works when the base is heavy and stable. Something like a monolithic slab. That is, when oscillations capable of destroying a point connection arise very rarely. And then there are no guarantees. A film floor is ideal when laying under a laminate, but under a tile it is not too good even with holes.

Core infrared floor: the point is in the design

This heater, in theory, is very good for tiles. These are carbon rods connected by wires. The rods are connected in parallel, which increases the reliability of the heater. When one of the rods burns out, the rest work. From this side everything seems to be normal.

The rod heater for the floor is laid in a layer of glue. Provides excellent traction to the base. The area of the heater itself is small - these are thin rods. And the space between them is filled with glue. So on this side, too, all is well.

Core floor heating is unreliable

Core floor heating is unreliable

The problem is that this type of heater often fails. Specifically, the rods are fired off at the points of attachment to the wires. It seems like nothing to worry about. If one or two rods do not work, this is not a problem. The rest are working. But others gradually stop working. When several pieces burned out, more current goes to the others, which leads to overheating of the connection and they simply can not stand it. And while this problem has not been resolved.

Choosing the best option

To summarize. The main criteria for choosing a method of floor heating - reliability and durability. After all, repairing a heated floor under a tile is an almost impossible undertaking. It is necessary to remove the tile and break the screed or layer of glue. To do with little blood will not work. The only way.Based on these considerations, there are only three types of more reliable underfloor heating under the tile:

Special glue and grout required for installation

Special glue and grout required for installation

- water,

- resistive cable

- cable mat made of resistive cable.

Not such a wide selection. But there are still design options, so it actually turns out a little more.

Water and cable ties

The device of a water floor and cable is possible only at the stage of major repairs. They are stacked in a screed, and it should ripen for 28 days. But the screed works like a heat accumulator and evens out the temperature. What is the difference between these two types of heaters? In that:

- water requires more funds (more equipment and it is more expensive),

- the screed with the water floor should be thicker (5.5-6.0 cm vs 3 cm),

- the load on the overlap of the water heating is greater (due to the thickness of the screed and due to the fact that the coolant also has a considerable weight).

The cable must be laid out and secured, then pour a layer of concrete

The cable must be laid out and secured, then pour a layer of concreteBut the water floor is more economical to use. But in an apartment it is almost impossible to make it legally. No one will give permission to connect to the heating system. To put a separate boiler is to increase already considerable expenses. And not every overlap can withstand such an increase in load. An exception is new homes that have special risers with a lower temperature, and floors are designed taking into account the possible arrangement of a water heated floor.

Water and cable without screed

There is also a “dry” way of laying water or cable underfloor heating. It is good if you do not mind making the floor lagged. The board does not fit on the lags not close to each other, but in spite of it. If the board is too expensive, loose chipboard, thick plywood or other similar material will do. Metal heat distribution plates are stacked on the boards. A groove is formed in the center of the plate into which a pipe or cable is laid. A sheet material (plywood) is placed on top, it is already possible to lay a tile on it with glue.

Dry installation of water and cable floors

Dry installation of water and cable floors

As you can see, the design is multi-layered. Floor heating is not direct (directly from the heating element), but through the heat distributed by the plate. And the plate is heated first, plywood from it, and only then a layer of glue with tile. So it will take a long time to heat such a floor. And take the power of the heating element with a large margin. In general, this option is only suitable if a warm floor is needed so that the feet are warm. For basic heating - this is an unacceptable option.

Types of underfloor heating for tiles, their strengths and weaknesses

Tiled floors can be heated, in principle, by any heating system available on the building materials market:

- water,

- electrical, including: resistive (represented by heating cables and mats), infrared (film and rods),

- combined - electro-water.

However, the first available system is not suitable for every room. Here it is necessary to take into account various factors affecting the choice of type of heating, as well as the advantages and disadvantages of the listed floor heating systems.

Factors affecting the choice of underfloor heating

The choice of tile floor heating system depends on a number of factors:

- functional purpose of a heat-insulated floor,

- cement screed thickness,

- type of heated room,

- costs for the purchase of equipment and operation (it is understood that the installation will be carried out on their own).

Functional purpose. The type and type of heating decisively affects the power and appearance of a warm floor: primary or secondary. For example, calculations show that even the most effective infrared warm floors in terms of energy consumption are not affordable for the vast majority of the population when heating a living room on an ongoing basis (calculations can be found in the material “Installing an infrared warm floor under a laminate”).There is no alternative to a water heated floor.

When using a warm floor as an additional source of heating, on the contrary, you need to mount one of the types of electric floor.

Screed. The thickness of the screed is important in apartments with a low ceiling, as well as in the bathroom, where floors according to SNiP should be slightly lower than the main floor. For this reason, the installation of a water heated floor is excluded in the bathroom - it will necessarily rise in relation to the corridor and rooms.

Type of room. The appearance of the room has a double effect on the choice of a warm floor.

1. Calculations show that large areas to effectively heat a water heated floor. In small rooms it is better to install electric tile heating.

2. In multi-apartment buildings, the legislation of the Russian Federation prohibits the installation of a water heated floor. The reasons are as follows:

- the connection of the water floor to the central heating violates the temperature balance in the apartments of the entrance,

- a thicker screed with porcelain tiles increase the load on the floor, which is not designed for such operating conditions,

- there are difficulties taking into account the consumed thermal energy,

- in the case of a bathroom, the requirement of regulatory documents on a lower floor is violated.

The cost of operation. Comfort always costs money, but not at the expense of living standards. Therefore, choosing the type of floor heating from tiles, it is necessary to find a balance between the price of equipment and the cost of its operation with family income. It should be remembered that cheap equipment is not always economical. Sometimes it is better to spend significant funds at the initial stage, but to get savings in the future.

Based on the above factors, as well as the strengths and weaknesses of each type of heating, we will compare all types of warm floors with each other.

Water floor heating

Water heated floor uses a hot liquid (water, antifreeze or antifreeze) circulating through pipes laid in the screed as a heat carrier. The heat carrier is heated in special heating boilers. Depending on the fuel consumed, they can be gas, electric and solid fuel, where coal, firewood, pellets, peat briquettes, sawdust, etc. are burned.

The basic device for floor heating under ceramic tiles can be seen in the diagram below, where the numbers indicate all the elements of the floor.

- 1 - thermal insulation layer. Its installation is necessary to maintain heat. Otherwise, the floor slab or basement will be heated. As a heater, foil roll materials are mainly used: polystyrene foam or polyethylene foam.

- 2 - reinforcing mesh. It performs two functions: it serves as the basis for fastening pipes with a coolant and strengthens the screed.

- 3 - pipes with water or antifreeze as a coolant.

- 4 - a hydroregulator, with which the flow of coolant into the pipes under the screed is changed (in other words, the floor temperature is regulated).

- 5 - concrete screed. You can read more about the technology of screeds for underfloor heating in the material “Screed for underfloor heating”.

- 6 - tile adhesive.

- 7 - ceramic tile.

The water-heated floor has many advantages, which allowed him to lead the sales rating. Among the advantages it should be noted:

- high operational efficiency (the main advantage) - the cost of heating a room, compared with alternative heating systems, is much lower. For example, in rooms with ceilings up to 3 m high, compared to central heating, 20-30% of the family budget is saved, and in high rooms - up to 50-60%. When compared with electric heating, the costs are 4-5 times lower.

- long service life, at least 50 years,

- versatility - can be laid under tiles in any room of a private house,

- comfort - it’s nice to walk barefoot on warm tiles,

- environmental friendliness - there is not a single factor negatively affecting the health of family members,

- aesthetics - the heating system is hidden from view (there are no pipes or radiators).

There are also disadvantages:

- can only be done in private housing,

- it is necessary to have a technical room for installing a heating boiler,

- powerful floor slabs are needed - ceramic tiles together with a thickened screed create a large weight load on them,

- there is no possibility of repairing pipes inside the coupler during leakage - only complete dismantling of the floor,

- large thermal inertia - the mixing unit does not allow for fine, within 2-3 o temperature control. Sudden jumps are always observed, which is well illustrated by solid fuel boilers,

- the height of the room is reduced by at least 100 mm (insulation + pipes + screed + tile adhesive + tile),

- high installation costs: it is necessary to build a utility room for a heating system, buy a heating boiler, pumps, pipes, a mixing unit, etc., which is several times higher than the cost of a cable floor heating,

- complex and at the same time laborious installation process, requiring special knowledge on the design and installation of warm water floors,

- uneven floor heating at the inlet and outlet of the coolant - it cools as it passes through the pipes,

- solid fuel boilers need constant maintenance,

- high costs for heating 1 m 2 of the floor when heating small areas.

Conclusion: water floor heating in terms of operating costs wins with a significant advantage over similar systems with other energy sources. Another advantage is the durability of such a floor. But it is achieved only by properly installed and using high-quality components. However, the available disadvantages sharply limit the scope: only in the form of basic heating for a private house or cottage.

Cable electric floor

Already from the very concept of “cable underfloor heating” it is clear that the heating element is an electric cable with high resistivity. Electric current passes through it, heating it by analogy with an iron, electric stove, electric heater, etc. The cable transfers its heat to the screed, which, in turn, heats the tiles.

Heating wires are:

- single core

- two-core

- self-regulating.

Single-core cable (position A in the figure). The wire has one core, which is both a conductor of electricity and a heating element. It has two drawbacks:

- the presence of radiation, despite the braid of copper wire. With the constant operation of the system, the human body still feels a certain negative impact on itself. When using heating as an additional source of heating, the radiation dose is small. It’s completely harmless even for a child,

- The laying pattern should be such that both ends converge at the thermostat, which is difficult to accomplish with a complex room configuration.

The price of such a cable is quite low (from 120 rubles per 1 meter).

Two-core (B). This cable design involves two cores: one heating (heating element), the second conductive. The system completely lacks the disadvantages of a single-core wire: there is no radiation and there is no need to reduce the ends of the controller (at the end of laying, the wire is cut off and the cores are bridged, creating a closed loop). There are no restrictions for laying such a cable.

One minus is the high price (from 280 rubles for 1 pm).

For information: for heating a room with an area of 6-7 m 2 you will have to lay out more than 10.0 thousand rubles for the cable.

Self-Regulating (B). The most complex, and at the same time the most reliable floor heating system is a self-regulating cable. He has the ability to regulate his power in a certain area, focusing on the temperature of the floor at each individual point.Such a cable’s ability is embedded in its internal structure: two conductors with a polymer matrix in the middle, which serves as a heating element.

The price of 1 p.m cable is prohibitive - from 2700 rubles.

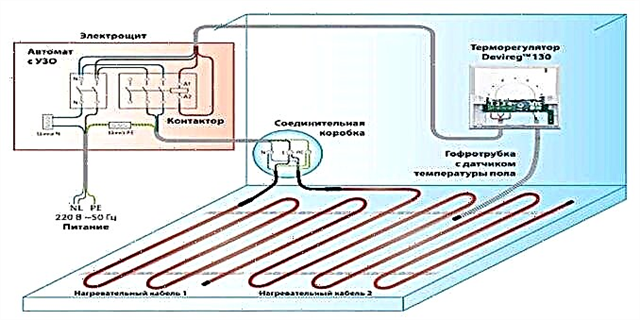

The cable floor heating device is shown in the diagram.

- 1 - concrete floor.

- 2 - insulation (usually a foil substrate of the Penofol type).

- 3 - mounting rails to which the cable is attached.

- 4 - heating cable laid according to the scheme.

- 5 - temperature sensor. Transmits floor temperature data to the thermostat.

- 6 - electronic or mechanical temperature regulator (controller).

- 7 - cement-sand screed, preferably with a plasticizer and fiber.

- 8 - tiled floor.

The advantages of cable underfloor heating include:

- ease of laying - all work can be done independently,

- environmental friendliness - all cable elements are environmentally friendly,

- universality - can be used in private houses and in city apartments, in small and large rooms,

- long term of operation - not less than 10 years,

- thinner, in comparison with water floor heating, screed,

- the possibility of repair - the screed is opened in a radius of 10-15 cm from the gap

- high power, which makes it possible to use this type of heating for basic heating,

- safety - the risk of electric shock is reduced to zero.

Disadvantages depend on the type of cable. One and two-core cable can overheat under furniture. Self-regulating cable is very expensive. In addition, it slowly warms up. A common minus is the high cost of operation.

Conclusion: this type of heating is well suited for tiled floors. According to the principle of price / quality, the best option is a two-core cable.

Heating mats

Resistive heating mats - in fact, the same cable underfloor heating, only looped on a reinforcing mesh made of polycarbonate. This combination of cable and net allows laying the tile directly on the mats, bypassing the stage of cement-sand screed (tile glue acts as a screed). Mats with single and twin-core cables are available.

A tile floor with heating mats is shown below.

- 1 - tile.

- 2 - tile adhesive.

- 3 - heating mat.

- 4 - rough screed (serves simultaneously as a heat accumulator).

- 5 - thin foil substrate (insulation).

- 6 - floor slab.

Important: in most materials on the installation of heating mats, the authors suggest laying the cable directly on the concrete floor, which is difficult to explain. Indeed, when using such a technology of a device for underfloor heating, there will be significant heat loss for heating the ceiling of the neighbors below or the basement in apartments on the ground floor. It should be remembered: all types of underfloor heating must be laid on a foil substrate (the underfloor heating in the bathroom under the tile is laid on foil without a substrate, which allows the lower floor requirement to be met).

For cable mats, the strengths are:

- high readiness for installation: the cable is laid and attached to a reinforcing fiberglass mesh,

- lack of screed over the warm floor,

- durability - a service life of more than 50 years,

- ease of installation - the work can be done by the owners of the premises without special knowledge and experience,

- quick installation - there is no need to wait for the full setting of the cement-sand screed,

- convenient calculation of demand (by area): there is no need to conduct complex calculations, determining the required cable length,

- the possibility of laying on a wooden floor - low weight load on the boards and logs due to the lack of screed,

- universality - there are no restrictions on the type of premises (kitchen, bathroom, toilet, corridor) and the type of buildings (private house, apartment, bathhouse, cottage),

- environmental friendliness - the cable and the reinforcing mesh do not contain materials harmful to health, and the degree of radiation is minimal, not harmful to health (according to measurements, electromagnetic radiation is less than that of a cell phone).

Minuses:

- low power

- maximum heating area does not exceed 15 m 2,

- cannot be used as primary heating,

- when laying directly on the insulation, it is prone to overheating. Therefore, it is necessary to make a rough screed between the substrate and the mat or use reflective foil without a substrate.

Conclusion: heating mats - one of the best options for heating tiled floors.

Infrared film

The basis of infrared floor heating is the ability of bodies heated above 60 o C to emit electromagnetic waves 0.75-100 microns in length, which, when encountered with a dense barrier, give it their energy in the form of heat.

Manufacturers of underfloor heating have adopted this principle and began to produce infrared emitters operating in the range of 5.6-100 microns. Such a warm floor consists of two layers of film, between which conductive strips (one copper, the second silver) are connected, connected to a carbon emitter. Passing through a carbon paste, the current heats it, as a result of which carbon black begins to emit infrared rays. Reaching the tiles, they intensively heat it.

A warm film floor is not an ideal option for heating a ceramic tile floor. It has significant drawbacks that narrow the possibility of application. But the advantages are impressive:

- the possibility of heating the floor only in those places where people are: a corridor, a working area and a resting place. In this case, electricity is used more rationally: there is no need to heat the lower part of the furniture (according to calculations, the savings reach 20-30%),

- the cost of the kit is much lower than other heating systems, cable or water,

- the IR film itself is saved, since there is no need to lay on the entire surface of the screed,

- can work in the temperature range from +200 o С (the plate can heat up to this temperature) to –70 o С, which allows using it in unheated rooms: a summer house or a country house in winter, where owners rarely visit,

- fast floor heating due to low thermal inertia,

- there are no administrative prohibitions on installation in apartment buildings,

- simple installation that does not require the skills of an electrician and a builder. It’s enough to carefully and pedantically follow the instructions

- there is no need for repairs due to the parallel connection of the strips. Failure of one will not affect the work of others,

- long service life even during continuous operation,

- the room warms up evenly, while the warm air is at the bottom, and not under the ceiling,

- there are no convection and injection air flows indoors, which gives an unexpected result: there are no indoor apartment drafts that raise dust (a significant part remains at the places of formation), which is important for allergy sufferers (do not get sick) and housewives (less cleaning work),

- infrared radiation is absolutely harmless to humans: completely identical to sunlight.

Among the minuses we note:

- tile cannot, unlike linoleum and laminate, be laid directly on the film. Need a protective intermediate layer of plywood, GVL, particleboard or OSB,

- very high energy consumption of carbon emitters, which costs significant amounts from the family budget when paying for electricity,

- The IR floor heating operates from a 220V network, which can lead to: electric shock, short circuit if water gets on the film, fire,

- dependence on the operation of power lines: there is electricity - there is heat, no - it will be cold,

- lack of ability to rearrange furniture. The film can easily withstand additional loads, but not the room will be heated, but the bottom of the sofa, cabinet or any equipment.

The need to close the radiator also changes the concept of a warm floor based on an IR film. In the figure below, the numbers indicate:

- 1 - cement screed

- 2 - foil insulation

- 3 - IR film

- 4 - a plastic film as a hydroprotection,

- 5 - plywood, gypsum fiber sheets, etc.,

- 6 - tile adhesive

- 7 - ceramic tile.

Conclusion: despite its advantages, it is advisable not to lay the infrared film floor under the tile - it loses to the heating mats.

Infrared rods

Manufacturers of underfloor heating took into account some of the shortcomings and disadvantages of cable floors and film systems and offered consumers their symbiosis: infrared rod mats.

The heating IR mat consists of current-carrying copper bars in heat-resistant insulation made of PVC and carbon rods 3 mm thick and 83 cm long in a polyester sheath, connected to the cables parallel to each other. Such a connection of the thermocouples of the heating system allows it to function in the normal mode when one or more rods fail.

Another remarkable property of infrared rods: the ability of carbon black to reduce the amount of energy consumed by increasing the temperature of the rod, which eliminates the risk of overheating of the heating element under the furniture.

Mats from IR rods have many advantages:

- profitability. Due to the ability of the rods to regulate energy consumption depending on the temperature of carbon black, there is a decrease in energy consumption as the floor is heated, which is well demonstrated by the graph below.

- light weight - reduced floor load

- corrosion resistance

- fire safety - when heated above 60 o C, the rods stop conducting current, which does not allow them to continue to heat up,

- moisture resistance - insulation of joints is made at such a level that the mats can work with partial immersion in water. Therefore, they are well suited for bathroom and balcony,

- environmental friendliness. And the materials from which the system is made, and infrared radiation do not pose a danger to humans,

- simple installation that can be done by a beginner without experience in this field,

- compatibility with all available floor coverings,

- quick heating of the flooring,

- frost resistance - maintains operability in frosts of up to 50-60 o C, which makes it possible to mount such heating systems in country houses and cottages where the owners do not live permanently in winter.

Carbon mats also have weaknesses:

- very high cost of the kit - prices start at 4,000 rubles. for 1 m 2

- complex system of connection to a temperature regulator,

- short service life - designed for 10 years.

Infrared mats for performance indicators are well suited for tiles. The styling scheme is simple. Shown in the figure below, where:

- a - screed or concrete floor,

- b - insulation

- c - heating infrared rods,

- g - tile adhesive

- d - tile.

Conclusion: despite the good performance, the high price of the kit prevents consumers from laying infrared rods under ceramic tiles.

Electro-water underfloor heating

Scientists and engineers all the most interesting ideas arise when trying to combine incompatible, at first glance, things into one system. This happened when creating an electro-water floor. Technically, the solution was presented in two versions of the warm floor:

Systems XL Pipe (X-L Pipe) South Korean company Daewoo Enertec, where antifreeze (liquid) was poured into a hermetically sealed channel made of heat-resistant plastic and a nickel-chromium heating cable was placed. The current passing through the cable heats it, and that, in turn, heats the antifreeze.

When the set temperature is reached, the power supply is stopped, and the antifreeze, which is constantly in a static position, maintains the temperature in the room for a long time. Such a heating system eliminates the need for expensive appliances and assemblies: pumps, mixing units, boiler, collectors, etc. You do not need constant care of the boiler, as he does. This allows you to significantly save the family budget.

Capillary electric underfloor heating UNIMAT AQUA (manufacturer Caleo, South Korea). This system is more like water heating.Only instead of the boiler a special device is used that heats the water, and centimeter-diameter pipes with a liquid coolant replaced thin tubes with a small diameter. The system has only 6 liters of distilled water, which allows the device to relatively quickly heat the liquid.

The system is closed. The movement of water through the tube is due to the pressure difference at the hot and cold ends. The disadvantage of this system is the same as that of a classic water floor heating: passing through a tube, the water cools, which leads to uneven heating of the floor covering.

The strengths of such systems are as follows:

- expensive and bulky components and assemblies are not required,

- automatic control,

- excludes overheating, and therefore can be mounted under furniture,

- suitable for all available types of floor,

- fast exit to the set parameters of heating,

- safe operation - no harmful emissions,

- economical consumption of electric energy,

- quick and easy installation.

The disadvantages, relative, should include a short service life of 5-10 years. It has not yet been possible to verify in practice, since systems appeared on sale less than 5 years ago. The short term of operation, only a couple of years, does not allow us to talk about shortcomings.

There are only positive reviews on the forums. Naturally, there are negative entries. But none of the critics cite specific examples and facts, only general reasoning. The editors of the portal also do not dare to give final assessments to such tile floor heating systems.

Laying pattern is standard:

- concrete base or screed

- waterproofing

- foil insulation

- heating system pipes

- screed

- glue,

- tile.

Conclusion: the emerging innovative system is of interest for heating small areas due to low energy consumption and the average cost of a set (about 10.0 thousand rubles). However, the short service life makes it difficult to use this type of heating for tiled floors - the replacement will be both time-consuming and expensive.

Which is better to choose

From the analysis of warm floors, several interesting conclusions can be drawn.

- In the private sector, under the tile, you can use any heating system. In apartments - only electric.

- Water systems are the most economical for basic heating of a private house. Electric heated floors can be used as additional floor heating in different areas, for example, in the bathroom, on a glazed balcony (loggia) and toilet.

- In apartments, the use of electricity for heating on an ongoing basis is ruinous, only as an additional one.

Electrical systems have their positive and negative properties. For an informed choice of warm floor, we bring them to the table.

Table 1. Comparative characteristics of electric underfloor heating.

| Features / Flooring | Cable | Heating mat | Film infrared | Rod infrared |

|---|---|---|---|---|

| Styling method | Stacked under a cement screed with a thickness of at least 30 mm | Stacked directly under tile adhesive | Stacked under GVL (gypsum fiber sheets) or under a cement screed 8-10 mm thick | Stacked directly under tile adhesive |

| Cost-effectiveness | Average | Average | High | Very high |

| Security level | Tall | Tall | Tall | Very tall |

| Warm Up Method | Uniform convection | Uniform convection | Heats items | Heats items |

| Kit price | Depends on the cable. May vary from low to high | Average | High | Very high |

| Reusable | No | No | there is | No |

| Electromagnetic field | 0.25 μT | 0.25 μT | Hardly ever | Hardly ever |

| Life time | More than 30 years | About 50 years | More than 30 years | About 10 years |

| Warranty | 15 years | 20 years | 20 years | Up to 5 years |

Based on the parameters given in the table, it is possible to more consciously determine which electric underfloor heating under the tile is better.

The editors of the portal Stroyguru.com make their choice and advises to buy under the tile heating mats or infrared rods. They are easy to install and economical to operate. However, the high price of the kit and the short life of the rods makes the cable mats the undisputed leader in our ranking.

The best manufacturers and models of underfloor heating for tiles

To protect yourself when buying underfloor heating from future problems, it is better to buy products from trusted manufacturers. Let a little more expensive, you have to pay for the brand, but with a guarantee of excellent quality. In the ranking of the best manufacturers are enterprises in Germany, Belgium, Russia, Sweden and other countries.

Valtec. The most famous brand of warm water floors in the CIS countries. The head office and equipment manufacturing is located in Russia. Pipes are made in Italy. Valtec products compares favorably with imported analogues in the price of the kit and a long warranty of 10 years. Responsibility to customers is insured at VSK.

REHAU. Another manufacturer of water heat-insulated floors with an impeccable reputation is REHAU (Germany). The brand of the company is known even to people far from construction and repair, since tens of thousands of various goods are produced under this brand.

According to the manufacturers, the underfloor heating produced by the company can run smoothly for 50-100 years, thanks to the pipes made of cross-linked polyethylene (they can withstand water shocks and mechanical stress, they are resistant to plaque formation).

HENCO. Products of the Belgian company HENCO comply with all DIN standards. The main feature of the company warm floors is unusual multilayer pipes. Inside, welded aluminum pipes with thin walls, outside the shell is made of PE-Xc polyethylene.

The whole range of products is presented on the Russian market. However, on sale you can find fake. Therefore, firstly, you need to ask the seller for a certificate of conformity, and secondly, remember that underfloor heating is produced only in Belgium.

THERMO. The Swedish company Thermo Industri AB produces the best in the world, according to experts and experts, warm electric floors. One of the first to form a market for these products in Russia, coming to Russia and the CIS countries in 1991. A wide range of products is provided by several production facilities located in Sweden and Russia (Thermo AB trademark).

The peculiarity of the product is that it can be mounted not only indoors, but also outside, for example, steps of the porch.

TEPLOLUX. Production facilities of Teplolux (one of the companies of the Special Systems and Technologies group) are located in the Moscow region. The produced electric floors are mainly sold in Russia, Belarus and Kazakhstan. There are sales offices of the manufacturer in other countries of the former Soviet Union, but sales are not so active there.

Domestic materials are used for the production, but the machines and equipment of only the best world manufacturers, such as Spirka and Dunst (Germany), Nokia (Finland) and Rosendahl (Austria).

A wide range of products allows you to select warm electric floors for any room, both in size and in operating conditions. For example, the Teplolux Mini models are ideal for a bathroom or toilet, and in the cold rooms that require a stronger heating system, the warm Tropix lux floors will do their job well.

For all its models, the manufacturer has set a life of 50 years with a warranty of 20 years.

National comfort. Another Russian company established in 1991. The products are distinguished by high quality and many innovative solutions - there is our own design bureau conducting high-tech research.

Important: the listed companies were rated based on consumer reviews and expert opinions, and not as a result of an advertising campaign. The material is purely informational.

The basic principles of the device underfloor heating for tiles

When installing underfloor heating, you need to adhere to several basic rules that allow you to get an effective heating system.

- Underfloor heating does not need a screed on the base. The system can be mounted directly on the ceiling. This will win a few centimeters of the height of the room.

- Overlap without fail is waterproofed. For work, you can use liquid glass or bitumen. Particular attention is paid to bathrooms, where the waterproofing film is additionally laid on top of the heating system.

- Foil insulation is laid on the waterproofing. Its thickness depends on the level of floors in different rooms and the height of the ceilings. It should be borne in mind that the thinner the insulation, the more heat is expelled.

- It is advisable to reinforce the screed over the heating systems.

- For final leveling of the screed, with level differences in height up to 1 cm, you can use tile glue. If this figure is exceeded, use self-leveling mixtures (bulk floor).

Necessary materials and tools

To install a warm tiled floor, you need to buy a set of heating mats, as well as auxiliary materials and assemble (buy, rent from neighbors, friends) a set of tools:

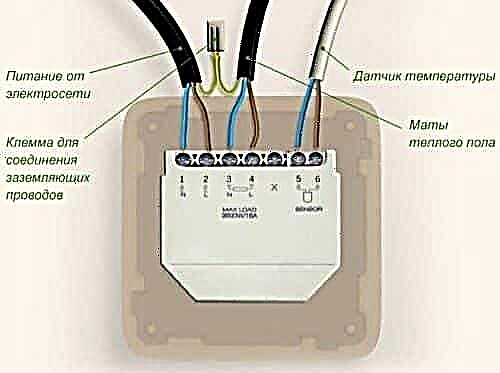

- a set of mats with a single or two-wire cable, which should include: mats themselves, cold ends, corrugated tube, temperature sensor with wires, temperature regulator,

- waterproofing mastic,

- box for thermostat,

- tile adhesive

- tile.

If the kit does not include any of the above list, then such an element of the system is bought separately.

In addition, you will need:

- Terminals in the form of a sleeve (one for each connection) with heat-shrink insulation

- heat-shrink tubing,

- silicone glue.

Of the tools at hand should be:

- hammer drill

- Bulgarian,

- knife or special device for stripping wires,

- Phillips screwdriver

- tester,

- building hair dryer or lighter,

- scissors.

Preparatory work

Preparing the base of the floor for installing warm electric mats is one of the important stages of the whole process. The step-by-step algorithm includes the following operations:

- all the furniture is taken out of the room,

- the old screed is broken

- the floor is being repaired. How to conduct the first operations correctly, you can see in the material "Preparing the floor for pouring screeds",

- the surface is primed

- a layer of liquid or paste-like waterproofing is applied,

- a heat-insulating substrate is laid, covered on one side with a layer of foil or lavsan.

Installation instructions for electric underfloor heating

Laying a warm floor under the tiles with your own hands is carried out in the following sequence:

Attention: the installation of the electric underfloor heating under the tile is painted according to the already installed screed, under which there is a layer of waterproofing and insulation.

- a layout diagram of the location of the mats is drawn up,

- the location of the thermostat is determined. It should be at least 30 cm above the floor. When installing a heated floor in a bathroom or a bathroom, the temperature regulator should be carried out into the corridor, where there is less dampness. In practice, this condition is often not met, which sometimes affects the quality of the device. Cases of device failure during the warranty period, which the manufacturer cancels if the conditions for the location of the thermostat are violated, are also recorded. Then, the strobe lines for the power cable and the temperature sensor are marked (the cold ends of the heating mat can be laid next to the temperature sensor cable). The sensor should be approximately 50 cm from the wall,

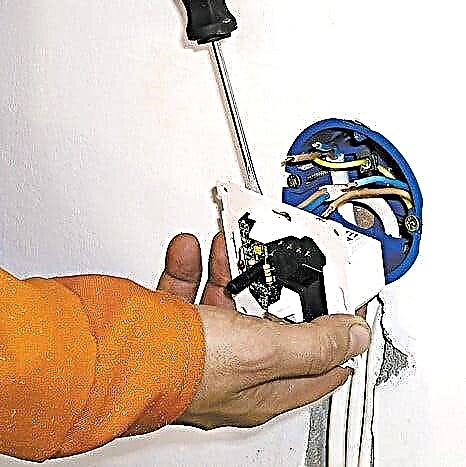

- an electric drill or a puncher with a crown cuts out a nest for a box (the number of nests depends on the model of the thermostat and the connection diagram),

- in the wall and on the floor a channel 20x20 mm (stroba) is cut out. The easiest way to do this is with a chaser. When doing the work yourself, you still have to use other tools: a grinder and a punch.

A grinder is cut along the canal lines.

Using a puncher with a spatula between the sawn lines, the wall breaks off, forming a channel for laying cables. This work can be done manually, with a hammer and a chisel, which is laborious and time consuming,

- the base of the floor is sweeping or vacuuming, after which it is primed,

- the temperature sensor along with the cable is inserted into the corrugated tube,

- a corrugated tube with a temperature sensor is laid in a stroba on the floor, and then laid in a channel in the wall. To prevent creasing, the turning radius should be at least 5 cm,

- along with the corrugated pipe, the cold ends of the mats are laid,

- the stroba in the floor is sealed with tile glue,

- in the bathroom and the bathroom, the floor is first primed and then treated with a waterproofing compound (you can use Knauf Flehendicht water dispersion insulation, PLITONIT HydroElast mastic or Cerezit CL 51 mortar),

- the layout of the mats from the thermostat begins according to a pre-compiled scheme. This beginning is due to the requirement to lay the cable loop so that the temperature sensor is in its center both in length and in width.

Attention: if the installation of the underfloor heating is carried out on the floor, after waterproofing, a heater with heat-reflecting foil is laid.

Joints of insulation are sealed with construction tape or special tape. So that the tile adhesive has contact with the overlap, between the cable loops of the foil substrate, holes are cut in size 50x150 mm at a distance of about 1 m from each other. The windows should be staggered.

Mats roll out over the floor.

To change the laying direction, the polycarbonate mesh of the mats is cut with scissors. Cutting must be done carefully so as not to touch the cable.

The distance between the cable loops of adjacent strips should be at least 5 cm. At the same time, the intersection of wires is strictly not allowed.

In difficult areas, the mats can be put in the form of a trapezoid or stretched diagonally.

- mats are attached to the floor surface either with a self-adhesive base, or with silicone hot melt adhesive. Such fixation is sufficient so that the sections of the mats do not move before applying tile adhesive,

- wire switching is carried out.

First, insulation is removed from the wires, approximately 10 mm.

Then, a crimp-type terminal is taken and mounted on the power wire. Here you must ensure that the connection provides good contact between the wire and the terminal conductor.

A heat pipe is put on the connecting wire (the cold end of the mat) to seal the connection of the wires.

After that, the stripped end of the cold wire is inserted into the terminal and crimped carefully.

The mounted connection is heated by a hairdryer - the heat-shrinkable insulation of the terminal will shrink, ensuring a tight connection.

The heat pipe moves to the junction of the wires and is also heated by a hairdryer or open flame of a lighter,

- All connections are checked using a tester. The results of cable resistance ringing should not differ much from the stated indicators in the passport,

- the box is installed, and then the thermostat,

- all cables are switched with the temperature controller according to the scheme of the manufacturer,

- tiled glue is being prepared

- with a notched trowel, tile adhesive is applied to the electric mats,

- ceramic tiles are glued.

The nuances of laying tiles can be found in the material "Laying tiles in the bathroom with your own hands."

Conclusion

The article considers the following positions:

- what warm floor is better to choose a tile,

- what materials and tools are needed to install electric mats,

- types and order of preparatory work,

- instructions for installing a heated floor for tiles.

From the above materials it is clear that the work is not difficult and can be done on their own.

Here you will find out:

To navigate the choice of a warm floor for a tile, it is worth paying attention to such nuances:

- Functions The power and, accordingly, the type of floor heating depend on whether the system will be primary, secondary or alternative. If the underfloor heating is intended for additional heating, the choice is wider.

- Screed. It is necessary to decide whether a concrete screed will be made during the arrangement of the floor. Also of fundamental importance may be the question of its thickness, especially when it comes to a room with a low ceiling.

- Type of dwelling. If in private houses almost any decisions are acceptable, then owners of apartments in high-rise buildings are often limited in their choice of heating systems.

- The cost of the system itself and its operation. Cheap equipment is far from always the most economical. When choosing a warm floor, everything should be taken into account: the cost of materials, the complexity of installation, consumption and the price of energy resources.

In any case, it is better to put a warm floor under the tile, because the material is very cold to the touch and it is unpleasant to become feet on it.

However, the type of system should be chosen wisely. It should fully fulfill its functions, rationally spend resources.

Water floor - a profitable solution. Although the installation of the system is time-consuming, and the materials are expensive, these costs and troubles are paid off due to the extremely rational consumption of resources

When choosing a system, you must also consider the features of its maintenance and repair. It is desirable that the equipment has free access in case of breakage.

What type of underfloor heating is better to use for tiles

Heat sources for flooring can be hot water and electricity. In the first case, water pipes are used that are mounted in the thickness of the floor, and among the electrical devices there are heating cables, mats and film underfloor heating. Which one is better to choose a warm floor for tiles has to be decided based not only on the cost of installation and operation - much depends at least on whether it is equipped in an apartment or in a private house.

Types of electric underfloor heating: pros and cons

One of the best combinations is a tile with an electric heated floor. Such a cake is easy to install, in comparison with a water heated floor, because most of the types do not need concrete screed. We conducted a comparative analysis and determined which floor is better - water or electric.

The main plus of the electrical system is the possibility of year-round operation. Underfloor heating is of an electric type in design, method of heating and installation.

Cable floors

Cable-type electric underfloor heating is the cheapest and easiest model that does not require additional maintenance. Suitable for both apartments and private houses. The service life is long. It looks like a simple wire that is fixed to the floor with an indent of 10 cm from the walls, and is poured with a screed. Electrical devices of this type are divided into:

- Resistive - are made from one or two-core cable, the difference lies in the connection method, but they operate on the same principle. The current passes through the wire, leads to heating of the cores that transmit heat to the screed, after which warm air disperses around the room and heats the area evenly. The twin-core is better suited for the bedroom, and in the living room, where people are less time, you can put a single-core, thereby saving the family budget. The cost of resistive electrical warm systems is much lower than other types. In addition, it is possible to lay this type of floor in rooms with a non-standard layout.

- Self-regulating - by the principle of operation they differ from the resistive type. In this design, two wires run in parallel in one braid. A polymer semiconductor is placed between them, through which a transverse current is supplied.

In a self-regulating device, ambient temperature affects heat transfer. This option is best used for tiles, since it does not lead to overheating of the surface of the warm floor.

Before putting the cable view of the underfloor heating under the tile, it is necessary to carry out calculations and draw up a layout of the contour. In this design, a screed is required, its thickness should be 3 - 5 cm, so that it completely covers the heating elements.

The presence of a concrete layer significantly increases the load on the floors, and raises the floor level, however, the concrete layer is not as thick as when building a water floor. When using a thin cable under a tile, it is allowed to install it in a layer of tile adhesive.

The main disadvantage of this underfloor heating is that if the heating element is damaged, the entire structure breaks down. Major and expensive repairs will be required.

Worth apt. meter cable 1,5 thousand rubles, and laying square. meter will cost 1 thousand rubles.

Thermomats

This is a type of cable floor, but with a more convenient shape, so it is considered the best option. The wire is fixed on a special fiberglass mesh with a snake, this greatly simplifies the installation process.

Another plus - thermomats can only be laid in a separate area in which heating is required. The thickness of the grid is only 3 mm, so they are better suited for rooms with low ceilings, as they do not reduce the distance from the floor to the ceiling.

Electric heating mats are:

- single-core - they are not expensive,

- two-core - their price is higher, but they are safe, since they do not have electromagnetic radiation.

Thermomats are the best option that can be put under the tile. In this case, no screed is required. Laying is simpler than cable pie, and efficiency is no less. Mats are placed on the rough floor, fixed on glue and covered with a decorative coating (tile). If necessary, notching is allowed to rotate it in the right direction, the main thing is not to damage the wire.

The positive side of the mats, which distinguishes them from cable floors - when the mats are connected in parallel, the output of one of the structural elements does not stop the operation of the entire device.

Their main disadvantage is the high price. If we compare the cable floor and mats, if they equip the same area, then the thermomats will be 30% more expensive. Installation of mats will cost an average of 750 rubles. per sq. m, and the price for a set ranges from 2 to 2.5 thousand rubles. per square meter

Film systems

The infrared film is made in the form of mats, 1 mm thick. This is the best option for rooms with a low ceiling height, since the film thickness is small, it does not take up usable area. The heating element is carbon strips connected by copper tires, located between the layers of heat-resistant polyester.

The device works due to the emission of infrared waves, which warm the surface of the floor covering. The resulting electromagnetic field is weak, therefore, does no harm to humans.

Adjustment of the warm floor is carried out using a temperature sensor. There are models whose work can be programmed for a long time.

The main advantage of this type of heating is the simplicity of installation, and that the temperature of the heating elements themselves does not increase, that is, energy is not wasted. However, it is worth noting that this underfloor heating is not recommended to be placed under the tile, since the film adheres poorly to the tile adhesive, thereby reducing the efficiency of the floor.

In addition, the film is exposed to moisture, and it does not have grounding, so installation with a screed or in rooms with high humidity is not acceptable.

You can choose an infrared film warm floor for laying tiles if you wish, but this will require a number of additional steps. It is necessary to lay a fiberglass mesh and lay a substrate of GVL sheets on which the tile will be installed.

But such a system should be used only if other options are not suitable, since the installation is complicated and the film has a high cost. Sq meters of film from 450 rubles, and installation will cost 500 rubles. square meters

Core infrared underfloor heating

The core floor heating (for more details about this type of heating, see this article) also applies to the infrared heating system. It consists of two conductors located in parallel, between them are heating rods. In the process of supplying current, infrared waves are emitted, which heat the surrounding space.

The best sides of the device:

- the rods are independent - if one is broken, the whole structure continues to function,

- self-regulation - when the temperature rises or when overheating, the device turns off,

- placement under heavy objects is allowed - which allows furniture to be rearranged.

Electro-water heating

Electro-water heating is a construction of polyethylene pipes with a diameter of 2 cm. Antifreeze circulates inside the circuit and a nickel seven-core cable coated with Teflon is extended. For such a warm floor, screed is required.

If the integrity of the communication is damaged, antifreeze seeps to the surface, thus indicating the place of failure. This facilitates the diagnosis and repair process of the structure.

The control is carried out by a temperature regulator, it automatically starts the heating process when the temperature decreases. The average consumption of electric water floor is 14.4 W / sq.m. When current is applied, heating elements are heated, which transfer heat to antifreeze, and it boils almost instantly.

Therefore, the floor surface quickly heats up, retaining heat for a long time. The model is resistant to overheating, in this regard, it can be laid under furniture without fear of consequences.

For your information! Since cooling antifreeze is a slow process, the energy consumption is small.

The best electric underfloor heating for tiles

If we talk about thermomats, then they can be laid on any rough surface, while it is not necessary to level it. After connecting the mats and connecting them to the network, tiles are laid on them using tile glue. This option of a heat-insulated floor is the best for laying under a tile.

An electric mat is the best option for tiling

When laying a film infrared floor, there are certain limitations. Some of its types can not be mounted under the tile, so before buying, you must definitely ask the seller a question or study the instructions on your own. IR film should only be laid on a level surface and is rarely used under tiles.

It is recommended to lay the cable floor in a screed, which increases its efficiency. First, install the cable and pour 4-7 cm of screed, and after it dries, lay the tile.

Ceramic tile has a number of advantages, the only drawback is that it is cold. Heated floor under the electric tiles will help to make your stay in the bathroom comfortable.

You can familiarize yourself with the rules for installing a warm floor under a tile here.

Pros and cons of electric floors

Electric heated floors allow you to quickly achieve a uniform and highly efficient heating of the room. The heat from them rises from the flooring immediately throughout the room where the heating system in question is laid.From the battery, the heat fluxes still have to disperse from the window to the far corners. At the same time, a considerable part of the air heated by radiators will remain under the ceiling, where no one needs it.

The advantages of electric underfloor heating

The advantages of underfloor heating on electricity are as follows:

- Versatility - such systems are allowed to be laid in bedrooms, hallways, kitchens and bathrooms.

- No even minimal risk of water leaks.

- Possibility of precise temperature control.

- Connecting to a conventional power grid without any tricks and installing additional equipment like boilers or boilers.

- The minimum period from the beginning of work to commissioning - the installation of a film electric floor in a small room up to 15 m2 takes a day.

- Uniform heating throughout the heated area over the heating system.

- Possibility of laying on top of almost any floor covering - tiles, linoleum, porcelain stoneware, laminate, etc.

- Ease of repair and high reliability - with proper installation, the risk of short circuiting is minimal.

- No need for complicated maintenance and seasonal preparation on the eve of winter.

- Minimum load on the floor - electric cables and mats weigh relatively little, and also do not require heavy thick concrete screed.

With a large area of heating, an underfloor heating system that runs on electricity consumes a lot of energy in kilowatts per hour. He needs about 100-200 W / m2. However, in the vast majority of cases, an existing 220 V network is enough for such a system. It is even easier to connect it to power supply than to connect a water heater to a water supply system or a dishwasher to a sewer.

Temperature distribution in the underfloor heating system

Among the minuses of electric floors for heating are:

- High power consumption.

- Possible problems with short circuits and electric shock.

To coordinate the connection of the electrical equipment in question, as in the case of a gas boiler, communal services and power engineers are not required. The main thing is that the electrical network of the cottage or apartment was designed for a connected load. If there is not enough free capacity, then you will have to lay another cable from the nearest transformer. And this can result in a lot of money.

Fastest tile laying

If repairs need to be done as soon as possible, only one type of underfloor heating is suitable for laying under the tile - a cable mat. It really fits quickly, and is reliable in operation.

The easiest and fastest cable mat in tile laying

The easiest and fastest cable mat in tile laying

What difficulties can be? Need a good tile adhesive for underfloor heating. It cannot be cheap. Consumption will be greater than when laying tiles on the screed. It is necessary to take into account the thickness of the heating cable and mesh. So the cost of tile adhesive will be significantly higher than without a warm floor.

Advantages and disadvantages of this system

A properly executed concrete screed, which hides the contours of water pipes, performs two functions:

- It acts as a reliable basis for laying hard coatings such as porcelain stoneware or plate.

- Acts as a powerful accumulator of thermal energy.

Heated from metal-plastic pipes laid in it, the concrete screed evenly distributes heat, transferring it to the ceramic tile.

A warm floor, functioning due to the water circulating through pipes, can rightfully be considered an economically viable option.

A significant drawback of this type of floor is its thickness. Only a cement screed “eats” 30-60 mm of height. In standard apartments, which are not characterized by high ceilings, "stolen" centimeters will immediately be noticeable.

In addition, the screed is poured for more than a dozen years. And it is not possible to provide access for visual inspection and prevention of the heating system.In the event of a leak and repair, it will be necessary to dismantle not only the tile floor, but also the concrete screed.

The total thickness of the “puff cake" when arranging a warm water-type floor is significant and is at least 70-100 mm

Experts do not recommend installing it in multi-storey buildings of Soviet buildings, since the interfloor ceilings used in those days were not intended for increased loads, which would be created by a massive heat-retaining screed.

When planning to connect a water floor to a centralized heating system, be prepared that not many companies give permission to take heat from the heating risers, as this may disturb its balance. And when connecting the system, in addition to the main expenses, the installation of expensive adjustment equipment will be required.

This is because the water temperature in the heating radiators and underfloor heating circuits is significantly different.

But for owners of private houses, a water heated floor is an ideal solution. After all, they are not bound by spatial restrictions and no coordination procedures are required to install the system. It is enough, following the manufacturer's recommendations, to install the equipment. In the future, maintain pressure in the system and circulation in the circuit, as well as control the temperature and quality of the coolant.

You can calculate the parameters of a water floor heating using our online calculator:

| Flow temperature, oC. | |

| Return temperature, oC. | |

| Pipe pitch, m | 0.050.10.150.20.250.30.35 |

| Trumpet | Pex-Al-Pex 16x2 (Metal-plastic) Pex-Al-Pex 16x2.25 (Metal-plastic) Pex-Al-Pex 20x2 (Metal-plastic) Pex-Al-Pex 20x2.25 (Metal-plastic) Pex 14x2 (Cross-linked polyethylene) Pex 16x2 (Cross-linked) polyethylene) Pex 16x2.2 (Crosslinked polyethylene) Pex 18x2 (Crosslinked polyethylene) Pex 18x2.5 (Crosslinked polyethylene) Pex 20x2 (Crosslinked polyethylene) PP-R 20x3.4 (Polypropylene) PP-R 25x4.2 (Polypropylene) Cu 10x1 (Copper) Cu 12x1 (Copper) Cu 15x1 (Copper) Cu 18x1 (Copper) Cu 22x1 (Copper) |

| Flooring | TileLaminate on the backingParket on plywoodCarpet |

| Screed thickness over the pipe, m. | |

| Specific thermal power, W / m2 | |

| Floor surface temperature (average), oC | |

| Specific heat carrier consumption, (l / h) / m2 |

In this video you can see typical errors when installing a water floor heating system:

What kind of warm floors are better for tiles

Here, everyone can decide for himself, especially since the above is described as much as possible about all the nuances of each system. You should not be guided by the “opinion of the neighbor”, because it is quite possible for him to have completely different operating conditions. So, what came up to him, in a particular case, may not fit at all. If you are not sure of an independent choice, then you can always seek the advice of a professional.

Recommendations of specialists

Heated floor can be built independently. It is preferable, of course, to have at least elementary knowledge in this area. After all, for example, the same infrared film requires the correct connection. Although some systems are easy to handle.

Regardless of whether the floors are done with your own hands or whether workers are invited for this, there are a number of tips that will help to carry out all the work efficiently. So:

- you need to understand that the floor will not be heated entirely, but only those areas where there is no furniture and other interior items - about 60-75% of the total area of the room, which means that they buy the material exactly at these percentages,

- Before laying the tiles, it is necessary to double-check the serviceability of the system, especially if the mats were installed (they can be twisted, broken or even have gaps),

- after all the elements have been put in place, you need to “ring” and double-check the joints of each floor section - it is cheaper to fix the breakdown before the finish coating is installed, then to make repairs not only at home, but also at the neighbors below,

- In no case should you walk on the laid heating mats, place or throw any heavy objects on them until the tiles are laid,

- if the repair is not finished yet, then you need to designate the “course” of all cables, so that in the future it doesn’t turn out that when drilling the walls (for example, under the shelves), they get into the wire,

- if the cable floor is mounted, then you can turn it on for testing only after the screed is completely dry (drying time depends on the mixture),

- when working with infrared film, it is necessary to use a substrate with heat-reflecting properties - experts recommend stopping on a roll technical plug (2 mm thick),

- Before fixing the infrared film, you must first lay the mounting fiberglass mesh (cell size - up to 3cm),

- To select the power of the thermostat, you need to carry out such calculations - 150 multiplied by sq.m. heated area

- for convenient operation and repair (if such a need arises in the future), it is recommended to use mounting cables of different colors,

- if the infrared heating system comes out more than 2W, then you need to use the connection through a special machine.

These tips were compiled by professionals, which means they are experienced. Therefore, if the plans to create a really high-quality heating, then it is worth listening to them.

Types of underfloor heating for tiles

The market offers a wide range of products for underfloor heating. Unified structural elements allow you to quickly install underfloor heating under the tiles. Manufacturers took care of home craftsmen. Assembly kits are on sale. The participation of the master is limited by following the recommendations specified in the instructions. The main work on the assembly of the circuit is carried out in the shops of the manufacturer. Installing a warm floor under the tile takes less time than preparing the surface with general construction methods and laying the finish layer.

Any complex tile pattern can be laid on the warm floor.

Any complex tile pattern can be laid on the warm floor.

It is difficult for an unprepared buyer to understand the proposed variety of products. Which manufacturer to choose, which model to stay on, what characteristics are optimal in a particular case? There are many questions. With apparent complexity, the answer can also be easily found. Information about all the methods that carry out underfloor heating for tiles will help to cope with the task.

According to the type of heating elements, warm floors are divided into the following types:

- Water. Mass distribution of space heating with the help of the floor began with this method. Today, underfloor tile underfloor heating is mounted mainly by home craftsmen. Costs are minimal since only inexpensive pipes are purchased. Connection is made to a standard heating system. The best option for a private house with an autonomous heating system. An economical way to heat. The disadvantage is a long warm-up.

Water floor heating scheme

Water floor heating schemeIn the houses of the old housing stock, it is forbidden to connect a warm floor on the water. The system is not designed for such heat loss. Prior to complete warming up, the neighbors are practically deprived of heating. City apartments with special heat-exchange risers are equipped in new buildings. If such a system is available, then installing a warm floor under the tile is possible.

- Cable. The classic direction. The era of mass industrial production of electric heater elements began with this view. Cable floor heating is regularly updated. Modern brands are practical, reliable and easy to install.

Cable floor laying

Cable floor laying - Heating mats. The evolution of cable underfloor heating, which stood out in a separate direction. A heating wire has already been laid on the synthetic mesh. Its cross section, as a rule, is less than that of a simple heating cable. It is convenient to install, easy to connect,

- Film. In fact, an electronic circuit of heating elements, divided into sectors, is assembled on a synthetic film. It is divided into parts exclusively according to the specified labels. The most economical and efficient way to heat.

The film look is designed for any flooring with the exception of ceramic tiles. The emitted IR radiation is blocked in this case. The efficiency is low, the thermostat due to overheating will turn off the system, preventing it from heating the decorative coating. You will have to refuse this option of underfloor heating under the tile.

Preparation for installation

The end result will be envious of the quality performance of this operation. Surface requirements are as follows:

- It is necessary to exclude the horizontal difference in height. If necessary, screed or leveling is performed. Deviations of 2-5 mm are permissible.

- Insulation of metal elements of housing construction. Inspection of the surface is required. Reinforcement, fixing parts of floor slabs, guide metal elements of the screed are removed or are reliably insulated with appropriate materials.

- Cracks, crevices, voids are closed with building mixtures.

- Waterproofing. It is relevant if installation is done. do-it-yourself floor heating under the tile on the first floor. Ground moisture is able to penetrate by capillary method above the soil level. The electric cable can be laid with guarantees of complete protection against the penetration of water. In apartment buildings, in addition to residents of the ground floors with an unheated basement, this operation can be neglected.

- Thermal insulation. The high level of energy loss through the floor, typical for some building structures, will require the installation of an additional protective layer. The operation is used in practice in cases where the heating efficiency is at risk. Modern residential buildings have a sufficient level of thermal insulation. The need to insulate the floor occurs with obvious signs of a "cold" floor and on the recommendation of professional builders.

- Before laying a warm floor, the prepared surface must be primed. Good adhesion of the filler composition with the base will create the prerequisites for reliable and long-term operation of the heating system.

Laying tiles on the heated floor according to the preliminary screed

Laying tiles on the heated floor according to the preliminary screedFor craftsmen with experience in general construction work, it is obvious that surface preparation is a basic operation on which the execution of the remaining steps will depend. A flat, horizontal surface ensures that the underfloor heating can be continued with the next step.

How to make friends with a tiled floor?

Compared with a radiator heating system, installing a warm floor under a tile has a significant advantage, since it allows you to create conditions for an even distribution of heat, while maintaining a natural and comfortable humidity for the residents of the apartment.

When arranging a floor trimmed with ceramic tiles, you can use one of two options:

Some choose warm water, considering it the most comfortable to use. With well-executed installation, he is able to create and maintain the optimal microclimate in the house. Others prefer the electric type, arguing their choice of the economic profitability of this type of heating.

To make a competent choice, you need to weigh the pros and cons, considering each species in more detail.

Features of the arrangement technology

The pipes themselves can be connected to a free-standing boiler or central heating. This type of heating is applicable both as the main source of heat, and additional.

The installation technology of a water floor includes a number of stages:

- Laying on the prepared base of the foil insulation,

- Reinforcing mesh for fixing water pipes,

- Installation of a system of plastic pipes,

- Pouring a sand-cement screed,

- Laying tiles on the adhesive.

The thermal insulation layer is designed to minimize the consumption of thermal energy for heating the base base.Foil insulation, reflecting heat, will redirect the flow up to heat the room.

Compliance with this condition is especially relevant when designing a warm floor in rooms located on the ground floors, under which unheated basements are located.

Option # 2 - electric floor heating

An equally effective source of heat is electrical energy.

Compared to water systems, they have several advantages:

- They can be used in private homes and in panel high-rise buildings.

- Installation does not require coordination procedures.

- The ability to adjust the temperature, setting the optimal mode for creating comfortable conditions.

Cable systems

An electric heating system can be implemented using a single, two-core or ultra-thin cable made of nichrome or another alloy, which is characterized by high electrical resistance. In this case, heating is carried out by converting the electric energy flowing through the cable into heat.

The cables laid over the entire surface of the snake are covered with insulating materials for added safety in order to prevent moisture and electric shock.

Laying cables for tiles in apartment buildings is not widespread. This is explained by the fact that they require filling the screed, which, taking into account the height of the cable, rises by 6-8 cm.

This option is most beneficial to owners who are just planning to carry out repair and finishing work on their living space. Then the floor heating system can be designed at the stage of creating rough base floors, reducing the loss of height of the walls of the room.

For more details about the subtleties of laying tiles on a cement screed of a warm floor, see the video:

You can calculate the parameters of a warm cable floor using our calculator.

Infrared underfloor heating

Film floors - the most modern of the presented options, the type of electrical system that can generate electromagnetic radiation, allowing you to create the most comfortable conditions at home.