One of the most popular design solutions used in the design of the kitchen is the installation of a corner. Such an interior item has earned popularity due to its functionality, attractive appearance and the ability to optimize the use of space. This is especially important for small rooms. However, in spacious kitchens, the corner will not be amiss - it will perfectly perform zoning of the space.

DIY kitchen corner - drawings and diagrams

What are kitchen corners

The piece of furniture, as the name implies, is set in the corner of the kitchen. The ensemble may include all elements: sofas (straight and angular), a table and chairs (stools). But most often the corner is purchased separately in the form of three modules: long sofa, smaller seat and corner pouf. Table and chairs (if necessary) are purchased separately by the owners.

As a rule, the configuration of the corner in assembled form resembles the letter G, however, U-shaped models are also available. The design may be solid or modular. In the first case, it is necessary to clarify the orientation of the furniture (right or left). Models are available that allow the use of a longer module as a linear element, while the second element can be installed at a distance. Small kitchens also fit perfectly with models with poufs symmetrically located relative to the corner element, each of which can accommodate one person. The corner can be installed even in a bay window, only its shape will be semicircular, triangular or polygonal.

Bay window sofa in the kitchen

For housing in which there are not enough sleeping places, and situations when it becomes necessary to accommodate a guest who has arrived with an overnight stay are not uncommon, a module with a full folding bed for sleeping will become a real salvation. At the end of the sofa, a minibar can be placed or a reclining shelf can be installed, which can be used as a bar counter.

Kitchen corner with a berth

Bright kitchen corner

Room dimensions

Kitchen interior items may vary in size and number of seats. It is necessary to select the configuration of the corner, taking into account the layout of the kitchen, its size and the rest of the situation. The installed corner should not serve as an obstacle to a comfortable stay in this room. A convenient option for kitchens with a lack of free space is a corner with a transformer table. If necessary, folding stools can be used as additional seats.

Options for kitchen corners:

- corner modules for four people

Four-person corner module diagram

- a model for a company of six

Model layout for six people

- compact model for three diners,

Corner for three people

- module with a berth.

Corner with a berth

Number of family members

The furniture installed in the kitchen should allow everyone living in the house to comfortably sit at the dining table. It is also necessary to consider the possibility of guests arriving. Of course, if the dining room is not intended for such gatherings. It should be borne in mind that a person of average build requires at least 60 cm for comfortable placement at the table.

The size of furniture will depend on the number of family members

Ease of use

The corner can be rigid or have a soft filler under the upholstery. In the first case, sitting on the sofa will not be too comfortable, especially not for a long time, but it will last much longer. In addition to the fact that the upholstery of soft models wears out faster, the filler itself has a useful life (for polyurethane foam - 10 years, for foam rubber (its elastic modification) - 3 years). In addition, rigid models are less prone to contamination. Such systems, as a rule, are cheaper than more comfortable counterparts. And you can solve the problem of excessive rigidity with the help of pillows.

Hard corner example

Availability of storage

The produced models allow not only to use the furniture for its intended purpose, but also to optimize the occupied space as much as possible. The presence of niches under the lifting seats in which you can store home belongings and products, or drawers is very helpful, especially for owners of small rooms.

Kitchen corner with storage

Material of which the housing is made

For connoisseurs of natural materials and comfort in the interior, corners made from solid wood are suitable. They are attractive and environmentally friendly, but usually quite expensive. An analog of a tree is LDSP and LMDF. These, cheaper and not always safe for health materials, are currently most often used in the manufacture of furniture. If desired, you can also purchase a corner made of metal. Metal structures are characterized by durability, strength and resistance to external influences, however, they can not be installed in all interiors. Often in production, a combination of different materials is used.

Metal corner for the kitchen

Modern kitchenette

Upholstery material

Choose the appropriate option, focusing on the design of the room and the functionality of the coating. For finishing, genuine or artificial leather can be used. Recently, the synthetic version has practically the same quality as the original, but its cost is significantly lower. The synthetic fabric with impregnation is also quite easily cleaned of dirt, does not fade in the sun and does not attract dust. Fabrics with aesthetically pleasing and pleasant to the touch nap are not so easy to care for. A beautiful jacquard that looks like a tapestry or suede can be expensive. A good option is a teflon coating on a fabric basis. Interesting models with a combination of finishing material.

Sofa upholstery may be different

Kitchen Style

This factor is closely related to the two previous ones. If the kitchen is decorated in hi-tech or techno styles, you can make a choice in favor of metal structures. For classic kitchens, wooden furniture is suitable. One thing is important - the installed corner should not get out of the general concept of decoration and furnishings.

The style of the kitchen is also very important.

DIY kitchen corner production

To assemble a corner for the kitchen on your own is a difficult task, but quite feasible. In the manufacture of furniture, the following steps must be completed.

- Remove the dimensions of the kitchen to determine the dimensions of the design and the option of placing furniture. The location of the door and window must be taken into account.

- Make a drawing of the assembled structure. You can compose it yourself or use ready-made options.

- Purchase materials and fittings. Cut according to the drawing.

- Assemble a corner from prepared parts.

Drawings of the kitchen corner from chipboard

It is easiest to make a corner yourself, the case of which is made of wood or wood-containing materials. Those who do not have very good carpentry skills or do not have a suitable tool can use the services of specialized organizations and order cutting parts according to their drawings there. Those who want to produce furniture on their own, at least, must have a circular saw, a milling machine, a screwdriver, a grinding machine and a stapler, if you have to upholstery with material.

Stapler prices

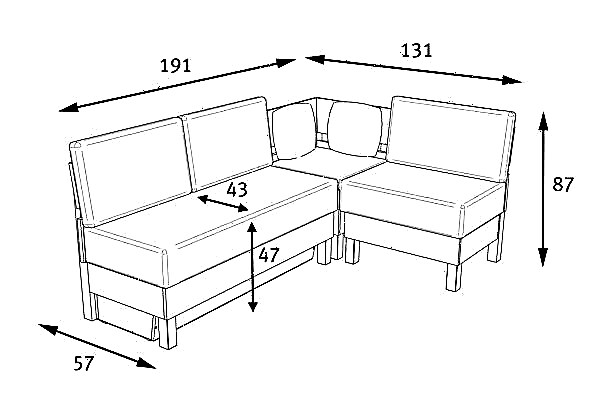

Average sizes for a kitchen corner, which will be convenient for being at a meal:

- height from floor to seat: 45 ... 47 cm,

- height taking into account the back: 87 ... 90 cm,

- the depth of the seat: 45 ... 50 cm,

- the total length is calculated individually, based on the needs and dimensions of the room.

Take for example the standard design with three seats on a long sofa and one on a short one.

Drawing of a corner for 3 seats

The height of the corner is 90 cm, the height of the seat is 45 cm, its depth is 50 cm. For the production of products you will need a beam of pine with a section of 5 x 5 cm, 3 x 4 cm, chipboard sheets, artificial leather for lining, foam rubber and synthetic winterizer as fillers.

Corner assembly technology (using the example of a long sofa)

Step 1. The first stage in the production of a sofa is the manufacture of a box.

First, the box is made

On the dowels (glued), the sidewalls, the bottom, the front wall of the frame are assembled. The result was a fairly simple design.

Parts are assembled on glued dowels

The back sides are joined.

Backrest

Cordless drill / driver prices

Support rails are installed.

Installation of support rails

For connection, self-tapping screws are used. The inclined supports for the back are attached.

Fastening the inclined supports for the back

The back of the chipboard is fixed with screws.

Fixing the back of the sofa

Horizontal rails are installed in the drawer, hinges are mounted on them (so far they only make money, they will be finally installed after the sofa is upholstered), with the help of which the box lid, which serves as a seat, will be lifted.

The size is cut off the rising cover of the box (also from chipboard).

Prepared box lid

Step 2 Upholstery is being prepared. Chunks of foam rubber are cut off.

Marking foam for subsequent cutting

Installation of soft filler is done on a special glue, which is designed for gluing wood and foam. Foam rubber is attached to all surfaces of the corner frame, except for the bottom. For the upholstery of the back and seat, a thicker material is used.

A synthetic winterizer is placed on top of the foam rubber (it reduces friction between the upholstery and the filler).

The synthetic winterizer is laid on foam

The skin substitute unfolds, the cover is sewn.

Important! It is true to take the dimensions for the manufacture of the cover and sew it - not at all simple. It is recommended to contact the relevant organization for this.

Material is reliably fixed on a corner. You can’t do without a furniture stapler.

The material is attached with a furniture stapler

Foam with padding polyester is also placed on the seat and covered with material.

Prices for the range of pneumatic staplers

Step 3 The frame on the back side is sutured with a thin sheet of chipboard.

The frame is sewn with a chipboard sheet

Sheathing material is attached to it, after which the back wall is also decorated with a skin substitute.

Back paneling

Loops are fixed. A seat is hung on them.

The seat is hung on the hinges

A small sofa is assembled and refined in the same way.

Sheathed small sofa

Furniture upholstery must be treated responsibly, since any defects made in the form of folds or protruding material will instantly spoil the appearance of the furniture. The second structure also has seat hinges.

The skin substitute is firmly fixed around the perimeter. The legs are fixed.

The result was a very attractive and stylish design, which, moreover, is distinguished by functionality, since, thanks to the rising seats, it was possible to organize additional storage places for various kitchen utensils.

The lift seats are very comfortable

It is not so easy to assemble such a design yourself. The most affordable assembly scheme for the kitchen sofa is as follows.

- The bottom perimeter of the frame is assembled from the beam. It is a rectangle, the width and length of which correspond to the size of the sofa. All wooden parts must be treated with protective impregnation.

Diagram of a simple kitchen sofa

Kitchen corner assembly

Ideal upholstery

When cutting foam, it is extremely important to consider the allowance for closing the ends. Soft filler and fabric are fixed with a stapler. A structurally simple, but elegantly decorated corner, made on its own, can adequately fit into the interior of any kitchen.

Location of communications in the kitchen

Upholstery of kitchen furniture largely determines the appearance of the structure. However, it should be remembered that the defects that appeared in the coating are not the reason to send the model that served faithfully to the scrap. Armed with a stapler and glue, having prepared a new fabric and foam rubber, you can quickly not only restore the appearance of the interior item by removing the material that has become unusable, but also give the furniture even more attractiveness.

Soft corner with shelves from Ikea

To minimize carpentry, you can use ready-made shelves from Ikea as a frame. To make such a corner with your own hands, you will need materials:

- Particleboard or plywood.

- Ikea shelves with facades.

- Upholstery fabric.

- Furniture foam rubber.

- Electric jigsaw.

- Drill.

- Construction stapler.

- Bolts and nuts.

Frame installation and fastening

By means of bolts, all structural parts are interconnected. But before that, you need to drill holes of the appropriate size in the side walls. If the drill does not fit in the shelf, then the hole should be drilled from the outside, separately in each wall. It is very important to make clear measurements so that there are no problems when connecting the structure.

In order to prevent the wood from deteriorating with strong tightening of the bolts, it is recommended to additionally use gaskets for the bolt and nut caps.

Installation of facades and seat bases

After the frame is installed, the facades of the shelves must be fixed. You can do without this, which will make the design much cheaper, but if you need additional space for storing various things, then you still need to install the doors.

The basis for the seats is created from sheets of chipboard (OSB) or plywood. Plywood with a thickness of 10 mm and more can withstand high loads and has good moisture resistance. The most economical option is to use a wood-particle board or oriented particle board.

The board is cut to the size of the corner with a jigsaw. Next, sand the edges with sandpaper of medium grain size.

Upholstery with soft material

It is important to use a special glue in the work, designed for strong bonding of foam rubber with a wooden surface.

The next step will be covering with fabric using a construction stapler. The distance between the brackets should be 1–2 cm. Even a person inexperienced in this matter can upholstery in plain material, but you will have to adapt to a complex pattern, because this task is no longer an easy task.

The finished seat can be supplemented with soft pillows, which will also serve as a backrest.

Cutting the shield and fastening parts

Before proceeding with the cutting of the shield, it is necessary to draw up drawings of a home-made kitchen corner with cuts. The project must be designed in such a way that at least 3 people can freely sit on the couch.

It is better to start cutting the shield with a jigsaw, but you can do with a hand hacksaw. During the cut, the tool should be held strictly perpendicular, and the ends of the shield should be located strictly at an angle of 90 ° in relation to the main plane.

The parts are fastened with self-tapping screws, and in order not to form cracks, it is first necessary to make a hole for the screw. The diameter of the drill should be 0.5-1 mm less than the diameter of the screw.

Making soft pillows

For sewing pillows, we use foam rubber, which, unlike sintepon and holofiber, has a more improved density and it is more comfortable to sit on it.

For the back, you can use thinner foam, and for seats you need foam rubber with a thickness of at least 80 mm.

If it is possible to work on a sewing machine, it is best to sew removable covers with zippers or buttons. This option is convenient in that the old fabric can always be replaced with a new one without extra costs.

DIY kitchen corner made of wood

A very simple, but original corner for the kitchen can be made from a wooden board with your own hands. To work, you need:

- Foam rubber.

- Wooden board 100x40 mm.

- Plywood or chipboard.

- Round dowel with a diameter of 15 mm.

- Drill with a crown of 15 mm.

- Jigsaw.

- Construction stapler.

- Batting.

- PVA glue.

- Upholstery fabric.

- Varnish and stain.

Sawing and grinding parts

First you need to create a drawing on paper or in a special program, and then you can start cutting the board into parts. To give the corner a more elegant look, you need to carefully cut out the curly details with your own hands. To make the elements smoother and more accurate, using a flexible ruler, you need to draw lines on the surface of the tree.

All parts are sanded several times with sandpaper of varying degrees of grain. Following, according to the drawing, the whole corner is assembled using dowels and glue.

Determined with design and construction

Before making the corner yourself, you need to determine its size. This will help to maximize the use of space. U-shaped headset is appropriate in a spacious room. The corner of the individual modules is recommended to be placed in studio apartments. In a cramped kitchen, it is better to install only an L-shaped design.

Before you make a kitchen corner with your own hands, you need to purchase materials for the frame and lining, given that the set will be intensively used. Its appearance should not discord with the design of the room. Upholstery is selected from materials that are easily cleaned from contamination.

When developing the design of furniture, it is advisable to make a sketch that will help to imagine how it will look surrounded by other interior items. It is better for an inexperienced master to make kitchen corners according to ready-made drawings.

Modular corners

Furniture of this kind is of interest for fans to experiment with its location in the room. Headset items do not hold together. More often a modular corner consists of 2-3 sofas. Sometimes they are supplemented with corner seats, which are a chair with 3 legs or on a 3-gonal base.

The modular suite belongs to the category of direct kitchen corners, the main disadvantage of which is the discomfort experienced by a person sitting in the corner.

With a berth

You can build in the kitchen such corners, which will sometimes be used as beds. The classic design of the headset is complemented by a couch. In the afternoon she serves as a seat. If necessary, it is moved to the rest of the elements. It is important not to make a mistake with the size of the couch. Its height should be the same as that of sofas. It is better to put it on furniture wheels, the size of which must be taken into account when developing the drawing. The kitchen corner with a berth can be modular.

With storage drawers

The best option for a kitchen is a corner with sofas equipped with drawers for storing things. They should be spacious and easy to open. Please note that the drawers may not allow people sitting on the couch to sit comfortably. Standing on the floor of the box should not interfere with the legs, so their front walls are recommended to be beveled or recessed.

Often, making a kitchen corner with their own hands, craftsmen place drawers not only under the seats, but also behind the backs of sofas. In this case, the area occupied by the headset space grows. Sometimes, instead of storage boxes, the frame is equipped with drawers. The assembly of furniture of this kind, in comparison with the installation of sofas with seat covers, is complicated.

For a small kitchen

Making a corner for the kitchen with your own hands, designed for operation in a limited space, you have to think about saving space. The dimensions of the room allow you to build a straight corner with small sofas.

Furniture is made in such a way that it is possible to store things, utensils, etc. in it. The design is limited in width and length so that it does not clutter up the room. It is complemented by light chairs or stools. For a small kitchen, you can make a modular set.

Necessary materials and tools

The following tools will be required to work on making a kitchen corner from wood:

- circular saw, hacksaw or jigsaw,

- drill,

- screwdriver

- elbow

- roulette,

- pencil and chalk

- mallet,

- stapler

- surface grinding tools,

- scissors,

- construction knife.

The fasteners will be:

- self-tapping screws

- confirmations

- furniture bolts with washers and nuts,

- dowels.

You need to purchase materials such as:

- 80 mm thick foam for seats,

- thin polyurethane foam for finishing the backs of sofas,

- dermatin, jacquard fabric, etc. for upholstery,

- masking fabric

- piano or furniture hinges,

- plywood or chipboard,

- Fiberboard

- bars 40x40 mm,

- staples

- ABS or PVC edge for trimming the ends,

- steel corners with holes.

For a kitchen corner from solid pine you need to buy boards 100x40 mm, plywood. The wood is planed with an electric or manual planer. The final grinding is performed with sandpaper or a tape machine. Only smooth, dried wood without signs of decay and cracks is suitable for work.

Drawings and schemes

A detailed drawing of the kitchen corner will help to avoid cost overruns and design errors. In addition to the general scheme of the product, the drawing must indicate the exact dimensions of the structural elements, the diameters of the holes and the cross-section of the fasteners. The novice master is recommended not to deviate from the implementation of the technical specifications proposed in the drawing. Keep in mind that replacing materials will affect the performance of the headset.

Based on the drawings for the manufacture of a kitchen corner, an experienced carpenter can make changes to its design, but you should not experiment with the height of the furniture. You can equip sofas with additional storage or adjust the length of the seats. With an increase in the size of the headset, reinforcement of the frame parts is necessary. Reducing the length of the structural strength of the kitchen corners does not affect.

Assembly

Exactly following the step-by-step instructions for assembling furniture will help the novice master to complete the work without unnecessary material and time costs. The process is divided into several stages, including:

- frame construction

- open and sew covers

- upholstery of backs and seats,

- headset assembly.

Before you make a corner in the kitchen with your own hands, you need to free the room from furniture and foreign objects.

Filler for a soft kitchen corner

Those who make a soft corner for the kitchen with their own hands use foam rubber as a filler. On the back you can put a sheet 20 mm thick. It is better to close the seat base with foam rubber from 40 to 80 mm thick. Durability and elasticity are characterized by polyurethane foam with a density of at least 30 kg / m³. Softer foam after a short time will hesitate.

The filler is fixed on the base with glue, which is applied to the contact surface of the wooden plate in a zigzag or staggered manner. At the edges of the base, polyurethane foam can be fixed with a stapler.

Sometimes the seats and backs of the corner are original mattresses and pillows. Covers can be filled with crushed foam rubber, siliconized fiber, etc.

What fabric to choose

Most often, the upholstery fabric for the kitchen corner is dermatin. It easily removes dirt. The material imitating expensive skin is cheap, durable and does not fade for a long time. For upholstery, you can choose microfiber. It is not inferior to dermatin in basic characteristics, but, in contrast to it, “breathes”. The disadvantage of microfiber is its short life.

Those who choose flock should know that inexpensive material is not practical, since its pile accumulates dust well. Beautiful, durable jacquard upholstery is expensive. Teflon fabric does not differ in cheapness, although it surpasses other types of upholstery in its properties.

Natural fabric is less suitable for decorating sofas: it gets dirty faster. It is harder to clean. The material is quickly worn away.

Fabric cutting and assembly

Before you make your own upholstery, you must accurately determine the size of the seats. When cutting fabric, it is necessary to take into account the thickness of not only the base, but also the lining. When designing the sweep, 1.5-2 cm should be added to the dimensions of the material. The side parts of the upholstery are sewn together. You can make a coating by combining fragments of different color and composition of materials.

How to choose the right project for the kitchen

When choosing an option, you need to focus on the area of the kitchen and the presence, location of other furniture: a wooden table, a refrigerator, a kitchen wall and other details. Next, it is required to take measurements of the kitchen, pay special attention to the area in which the installation of the corner will take place. Next, the following is measured (taking into account the previous values).

- The length and depth of each section of the sofa.

- The location of the sections.

- Frame height parameter.

It is allowed to use the drawings in the finished form. You can adjust them to your measurements. If there is no experience in designing, then it is advisable to contact a professional.

How to make a kitchen corner with your own hands

Below is a detailed plan on how to make a corner, consisting of two sofas: an elongated and shorter, and the third part - located between the sofas located in the corner. Drawings and schematic images are made with all parameters and in section. This article will tell you about sliding doors to the kitchen.

The choice of materials according to the schemes

Particleboard and plywood are used for the manufacture of the frame, and for upholstery they use materials that are affordable and of high quality. Here are a few commonly used options:

- Synthetics. These fabrics are very durable and easy to care for. The cost is quite affordable, cleaning is carried out quickly and efficiently.

- Imitation leather. The material does not absorb moisture, which is important in the kitchen. The care is also simple: just wipe it with a damp sponge and then wipe it dry.

- Microfiber. Ideal in the kitchen, very resistant material. If you make the upholstery from it, then the kitchen corner will last a very long time.

Under the upholstery fabric, it is necessary to choose a filler. The most inexpensive is foam rubber. But if you want the form of sofas to remain normal for a long time, it is better to use polyurethane, which has a better fiber structure. Its cost will be a little more expensive.

Tools

Pre-stock up with the necessary materials and tools. It is recommended to make a list so that subsequently everything you need is at hand. Below is a list of important tools.

- hammer,

- roulette,

- set of drills,

- drill,

- scissors,

- jigsaw or hacksaw (required for self-cutting sheets of plywood or chipboard),

- metal corner

- glue,

- edge for processing ends,

- fasteners (confirmats, dowels),

- stapler (special construction),

- furniture glides,

- hinges for fixing seats.

The first action is to cut plywood or chipboard.

Short sofa

Again, as with the long sofa, the details are first cut out. The dimensions indicated in the drawings should be clearly followed. Particleboard type (laminated or polished) is selected similarly to the choice in a long sofa. The assembly is the same.

Similarly, the sidewalls are made in the amount of two pieces, and the remaining parts in a single copy.

Basic rules for creating furniture yourself

Before you figure out how to make a kitchen corner with your own hands, you need to clarify the main nuances of furniture assembly:

- The accuracy of the work directly affects the functionality of the products, and the final result depends on many factors.

- At the stage of designing a kitchen corner, individual tastes and preferences of people are taken into account.

- If ready-made schemes are used for manufacturing, then you will have to work with the indicated materials. Otherwise, backlash and gaps will appear in the structure. It will require strict observance of the assembly order, as well as the selection of high-quality fittings.

- If there is no experience in creating furniture, you should give preference to the simplest straightforward models of kitchen corners with a concise decor.

- When choosing suitable drawings for a kitchen corner, you must be guided by the available tools. So, the manufacture of a wooden model does not do without a grinding machine, jigsaw.

To carry out high-quality assembly, you should think over the appearance of the kitchen corner in advance, determine the place where it will be located. This information will help you choose the most suitable materials and fittings.

The secret to the popularity of the kitchen corner is its aesthetic self-sufficiency. The corner sofa with a table form a separate comfortable area.

Frame

First of all, the frame of the kitchen corner is made - the supporting structure, on which all other elements are fixed. The configuration, strength, roominess of the product depends on it. To create kitchen corners with your own hands, natural wood and chipboard are suitable. Previously, it is worth evaluating the features of each material, the nuances of working with them:

- Particleboard is the cheapest and most affordable option. The pluses are that it has environmental safety and reliability. Difficulties in working with chipboards arise at the cutting stage. In production, the procedure is carried out using special machines. At home, work is more often performed by a jigsaw, which can lead to the formation of uneven edges and chips. Moisture gets into the damage; as a result, the sheets swell and deform. To prevent trouble you will need special edges, fixed on the saw cuts.

- A wooden corner is characterized by durability, strength, resistance to wear, environmental cleanliness - these are pluses. When working with the material, it is necessary to strictly follow the drawings, before assembly, treat the panels with special compounds that prevent rot.

For independent production of furniture, such breeds as linden, tree, birch, pine are best suited. They are the softest, easier to process and assemble. If conifers are used, it is important to take into account one more nuance - they must be thoroughly dried so that the resin does not stand out.

Natural wood is one of the most expensive materials, so it is better for beginners to train on simpler and cheaper raw materials. Particleboard will do.

Measurements and drawing

First of all, the length of the walls of the kitchen, as well as the corners of the room, is measured. The dimensions of all sofas are determined. Standard parameters are as follows:

- Seat height - 40-50 cm.

- Depth - about 50-70 cm, so that it was comfortable to sit at the table, but the legs did not rest against it.

- The height of the entire structure together with the back can reach 95 cm, but this is not the limit.

The easiest way to use ready-made drawings and diagrams, especially for people who are faced with the manufacture of furniture for the first time. It is enough to choose a plan that matches the desired size. If you adapt your favorite model to individual parameters, it is easy to make a mistake, and you will have to spend a lot of time on the alteration. The scheme should reflect all the features of the design: the availability of a berth, drawers and the nuances of their opening, the structure and location of the folding mechanism. It is important to be able to clearly assess the correctness of the drawings, not to take on the first example found on the network.

Corner manufacturing algorithm

The traditional kitchen corners with dimensions of 110 x 160 cm are optimal for three people. Products are convenient for a full meal by people without crowding and hitting each other's elbows. Creating furniture according to individual parameters has the advantage - it corresponds to the dimensions of the room. Upholstery is selected based on their own taste preferences and the overall style of the interior. The product can be supplemented with the functionality that is needed: a folding sofa for sleeping, storage places, or both together.

From chipboard with drawers

To make your own kitchen corner from chipboard, complemented by drawers, you need to perform several steps:

- training

- measurements of parameters

- drawing up a detailed drawing,

- purchase of accessories and fasteners, upholstery material,

- sawing wood-shaving sheets in a furniture workshop.

Designing begins with the choice of the optimal place where the sofa will be located. It is on the basis of its area that a suitable configuration and dimensions of the future product are selected. It is necessary to act according to the instructions:

- All elements are cut according to the template, polished.

- The edges are glued with tape.

- Assembly is carried out using dowels and confirmations. First, the short and long part of the sofa are connected, then - the seat with the back, which are attached to the sidewall, then the drawers are made.

- Compounds responsible for the stiffness of the product are fixed with metal screws.

- The final step will be upholstery. The filler is cut out of polyurethane plates. The size is needed larger than the elements for which it is intended. The filler is attached to the seat and back with glue.

To make a corner correctly, it is necessary to take into account the size of the kitchen, the placement of household appliances and furniture. At the narrowest point, the width of the passage should be at least 60 cm. The parameters indicated on the diagram may vary depending on the optimal dimensions of the model.

The standard values remain unchanged:

- seat height - 45 cm,

- depth - 50 cm

- the length of the large and small sofas is 120 and 200 cm.

The height along the upper edge of the backrest should not exceed 95 cm. The do-it-yourself corner for the kitchen is made of polished laminated chipboard with a thickness of 16 mm. To cut the slices, you need an ABS edge.

Simple wood

To make a simple set of wood, you must first draw a plan, carefully measure all the parameters. You can buy ready-made furniture panels for the received sizes. In total, 3 types of elements will be required: 6 identical sidewalls, 3 upper and lower boards each. Creating a model is done according to the instructions:

- All parts are cut across.

- The bottom board is located between the side, the top lies on them, like a lid. This feature should be taken into account when calculating the width of the material.

- The surface of the elements is carefully polished.

- Holes are drilled into which dowels are inserted.

- A kitchen corner made of wood is painted in a color that will be in harmony with the decor.

When making furniture, one should not forget about the importance of the location of dowels. It is necessary that they coincide with the holes in the contacting parts.

The product is painted twice to increase resistance to wear. After drying, the boxes are installed in the right place, optionally fastened to each other. A soft seat is placed on top, which you can purchase or sew on your own.

Connecting part

This is the most important, the third part, connecting the long and short sofas. Chipboard thickness must be at least 16 mm. From it you need to cut two slats for the back, then the workpiece, which will be mounted at the seat level. Next, you need to prepare a part of the back in the form of a trapezoid (located in the center of the kitchen corner). Lastly, the side parts of the back are cut out.

The assembly steps are as follows.

- The central part of the back with dowels and confirmations is attached to the side parts of the back.

- Thrust strips in the amount of two pieces are attached to the back. You will need metal corners and dowels for a secure fit.

- The prepared central structure should be carefully connected to the side panels of the long and short sofa.

- Then, by analogy, the seat should first be upholstered with foam rubber, and then stretch the material and secure it with a stapler. The brackets are fixed at a distance of 1 - 2 cm.

At the final stage, it is important to securely fix the central connecting part of the kitchen corner. Metal corners and confirmations are mandatory for stability. After fixing them, the kitchen corner is ready for use.

Seat mounting

From the same sheet of plywood or chipboard from which the bottom for the boxes was cut, you can make the base for the seat in size, which is indicated in the drawing. Working process:

Step 1. Take the foam rubber and cut out a piece of it, which should be 2-3 cm larger than the base on all sides.

Step 2. Glue the foam rubber to the chipboard.

Step 3. Cut the batting along the contour and glue it to the seat with the same glue.

Step 4. Using the construction stapler we attach the upholstery fabric.

It turned out an excellent corner sofa, which can become an adornment of any kitchen.

Selection and adjustment of pallets

First of all, you need to inspect the pallets that will be used for the manufacture of furniture for chips and damage so that there are no troubles during operation.

The size of the pallet is designed corner sofa. If space allows, you can make furniture from solid pallets, otherwise you will have to resort to using a circular or hand saw.

Connection parts

Making a corner for the kitchen or gazebo is not difficult, because for this you just need to connect the finished parts to each other with screws.

It is recommended to install pallets in two rows to make it comfortable to sit, taking into account the fact that there will still be a layer of foam rubber or a thick mattress on top.

To make the backrest, it is necessary to attach the pallet in an upright position to the base. This completes the assembly.

Materials and Tools

- manual hacksaw or jigsaw for harvesting parts,

- self-tapping screws

- nichrome thread

- foam rubber

- pencil,

- roulette,

- upholstery material

- loops

- drill,

- drill,

- paint (water based),

- brush,

- primer,

- metal corners,

- plastic glides.

Cutting parts according to drawings

- Draw up drawings and use them to cut parts from furniture panels or thick plywood. You can use a hacksaw or an electric jigsaw. Hold the tool at a right angle.

- Initially, the corner base is assembled: the bottom is attached to the front part, then the back wall is fixed.

- In the center, it is necessary to attach a transverse bar, which will not allow the structure to bend under the weight of the body of sitting people and will not lead to cracks in the material. From the inside and front, it forms an angle of 90 degrees.

- Then the side parts of the sofa are attached.

- The sofa №2 is made in a similar way.

- To make a corner in the form of the letter “G”, you will need screws that fasten 2 sofas to each other.

- Next, the backs are fixed from the back of each of the sofas. And in the joint zone they are connected with the help of confirmations. For reliability, metal corners are used.

- In advance, it is necessary to mark with a pencil the places where the fasteners will be, and then only screw the screws.

The drill is required to take 0.5 mm less than the diameter of the screws.

Lastly, lids (seats) are attached using hinges.

Cut details: what materials will be needed

- boards

- Chipboard

- stapler

- roulette,

- scissors,

- foam rubber

- upholstery fabric

- hand saw or jigsaw,

- sandpaper

- drill, nozzle for it - “crown”, diameter - one and a half centimeters,

- dowels

- batting,

- glue,

- varnish

- brush,

- pencil.

A detailed drawing is not necessary here, as they rely on the area of the kitchen. After the blanks, the following number of parts should be obtained:

- stand - 3 pcs.

- leg - 2 pcs.

- cross piece for a long sofa - 3 pcs. (identical) + 2 more,

- cross piece for a short sofa - 5 pcs.

- bars for sidewalls - 4 pcs. (2 on each side).

All cooked parts must be cleaned of debris and sanded well. First, coarse sandpaper is used. Gradually, you need to switch to medium and small.

Then you need to take a drill with a nozzle - “crown” and make holes for dowels. All components of the wooden frame are fixed with 2 dowels. Drilled holes should be well lubricated with glue, and then drive in the dowels and press.

It is very important to adjust the elements to each other at a right angle so that there are no distortions, a hammer will help to drive dowels. Internal corners also need additional reinforcement, a metal corner is used for this.