The Russian market of building and finishing materials is developing very rapidly. In the company "Gros" you can buy not only imported, but also domestic samples of high quality. One of the striking examples is the Russian manufacturer under the brand "Prospectors".

The company began its history in 1992, when it began production of finished putty. Later, the company switched to the manufacture of its main product - dry mixes. Most of the production is concentrated on 15 lines in the Moscow region, as well as in 4 branches across Russia.

Types of putty from the company "Prospectors"

For more than 20 years, putty remains the main product of the plant.

In the company "Gros" you can purchase all 9 of its types: basic, basic gray, facade finish, facade ordinary, facade gray, finish ordinary, finish KR (based on cement and polymer), finish plus, leveling gypsum putty.

In the production of putty "Prospectors" use various bases: gypsum, cement, polymers.

Basic putty "Prospectors"

This type of putty uses cement in its basis and is intended for indoor work. Ideal for rooms with high humidity, as it is moisture resistant.

The basic putty "Prospectors" is preferably used for application on walls and ceilings. It has excellent adhesion to concrete, brick and plaster. Other surfaces are best pre-primed. After applying "Prospectors" basic ", on top of it you can paint, apply decorative plaster or wallpaper.

Masters should pay attention that after solidification, which occurs after about 3 hours, the putty “Basic Prospectors” basic takes on a light beige color. Since putty is the starting one, it can be used to seal cracks and indentations in the applied surface.

On a standard twenty-kilogram bag of dry mix, the manufacturer recommends adding from 6 to 8 liters of water to obtain a solution. After three hours of "Prospectors", the basic use is not recommended. This putty is also produced in gray.

Facade putty "Prospectors"

Based on the name, the facade putty "Prospectors" is intended for outdoor work. This makes special demands on its composition: it is frost-resistant and has a high degree of resistance to all precipitation.

Manufacturers use cement with the addition of modifying additives as the basis for the mixture of facade putty “Prospectors”.

Better adhesion is achieved with the following types of materials:

– all types of concrete,

– brick,

– plaster (cement).

If necessary, you can also carry out interior finishing work using this putty, including in those rooms that require wet disinfection. This is possible due to the high degree of moisture resistance of the "Prospectors" facade putty. After drying, it will give a light beige color.

Putty is supplied in the form of a dry mixture in bags, so it requires the preparation of a solution before starting work. For each kilogram of the “Prospectors” putty mix, the facade needs to provide 300-400 milliliters of water.

It is necessary to pay attention to the fact that work can only be carried out in a certain temperature regime. It is not recommended to apply the “Prospectors” facade putty when the air temperature is below +10 or above +30 degrees Celsius. In addition, craftsmen need to avoid working in direct sunlight.

In the company "Gros" you can purchase several types of facade putty "Prospectors":

– front gray

– front finish.

Putty "Prospectors" finishing

When purchasing the Finishing Putty putty in the Gros company, it is necessary to pay attention to the fact that it is used only for internal work, in dry rooms.

Putty is plastic, as it is made on a gypsum base with the addition of polymers. Thanks to this, the output is pure white. Finishing putty "Prospectors" is used to cover walls and ceilings of concrete, brick, drywall, as well as pre-plastered surfaces.

After applying putty, it is possible to carry out not only painting, but also to glue wallpapers, including thin ones.

Unlike the two previous types, putty "Finders" finishing must be applied within one hour after receiving the solution. The solution is obtained by mixing a dry mixture of putty with water at a rate of 400-580 milliliters per kilogram.

One of the indisputable advantages of this type of putty is the absence of the need for grinding after drying, since it forms a smooth surface.

One of the types of finishing putty "Prospectors" is a putty with the designation "KR". It gives a perfect white color after drying, and therefore allows you to save on paint. Putty "Prospectors" finish plus is a mixture of cement and polymer and is used in rooms with high humidity (interior decoration).

For sealing joints, seams between sheets of drywall, the leveling gypsum putty of the “Prospectors” brand, which can be purchased at the Gros company, is best suited. It also helps to glue drywall sheets to a concrete or brick wall.

What was in the beginning

The production of such ready-to-use mixtures began by the Prospectors company back in the nineties. Technologists have taken as a basis samples of imported mixtures that have proven themselves in work. The base is made of cement and sand. Fillers are modifiers and plasticizers.

Description

The basic putty "Prospectors" is a dry mixture of white cement, which expands the field of use and accelerates the time of work. If we make a comparison with plasters based on gray Portland cement, the described composition has a light beige color, so the finish can be started immediately after the starting putty has dried.

If we consider the product by composition, then Prospectors can be attributed to dry plasters. However, one of the important differences here is the plasticity, which is characteristic of putties. This indicates versatility. The mixture combines moisture resistance, leveling properties that are characteristic of gypsum putties and plasters.

Using the basic putty "Prospectors", you can take advantage of another important advantage, which is expressed in the possibility of gluing wallpaper without additional puttying of the starting layer. This saves money and time.

The composition of the described mixture contains purified sand, the fraction size of which is 0.4 mm. The recipe involves the addition of gypsum and ground clinker. There are also additives in the mixture that prevent shrinkage and improve elasticity, and also contribute to the repulsion of moisture. The mixture contains polymer plasticizers and additives.

Starting putty is a modified mixture, because marble flour, fine sand and cellulose ethers are added to it, which helps to retain moisture and allows you to apply the composition in a layer up to one centimeter.

Basic properties and reviews about them

The basic putty "Prospectors" is made on the basis of the recipe, which is time-tested. Among the main properties of the product can be identified:

- plastic,

- water resistant

- high adhesion.

As for plasticity, the mixture can be smeared with a continuous thin layer, which is the main advantage. Application can be carried out using putty tools as a spatula or grater. On large planes, the composition is leveled without slipping and scoring.

Reading reviews of the basic putty “Prospectors”, you can understand that it is often compared with gypsum putties, which have less impressive adhesion to an uncoated surface. Consumers also like water resistance. When dried, the layer does not form pores. It is easy to grind until the grooves and tubercles disappear.

You can use the material both outside and indoors. It does not crack if applied in a thick layer. The mixture does not shrink. In this regard, according to consumers, you can use it to align walls with large differences and flaws.

Specifications and Consumption

The characteristics of the basic putty "Prospectors" are truly outstanding. This makes the mixture so popular among consumers. The working temperature range is quite extensive and varies from +5 ˚С to +30 ˚С. The basic putty "Prospectors", the technical characteristics of which are described in the article, begins to set in 1.5 hours after preparation.

In order to get the optimal consistency, you need to mix a kilogram of the mixture with 0.3 liters of water. The applied layer should have a thickness of up to 10 mm in one pass. You may also be interested in the strength of adhesion to the base, which is 0.25 MPa. The consumption of the basic putty "Prospectors" per 1 m2 is 1 kg. This figure is true if the thickness of the applied layer is 1 mm.

Application Tips: Surface Preparation

Working with any mixture according to the type of plaster, you can achieve a good result if you properly prepare the surface. On the walls should not be crumbling areas. If the coating peels off, it is removed. Painted walls are cleaned with graters, scrapers and rags. Previously, the layer must be softened with a construction hairdryer.

Brick or concrete walls are cleaned of spray, grout, lime and cement milk. The base should be cleaned of dust. Compressor units are usually not used for this; wide brushes are better suited. Cracks should be cleaned to remove crumbling material and putty.

At the final stage of preparation, it is necessary to apply a primer. It is selected depending on the porosity of the base. For foam concrete, for example, deep penetration primer is suitable. For ordinary concrete, acrylic-based film-forming compounds should be purchased.

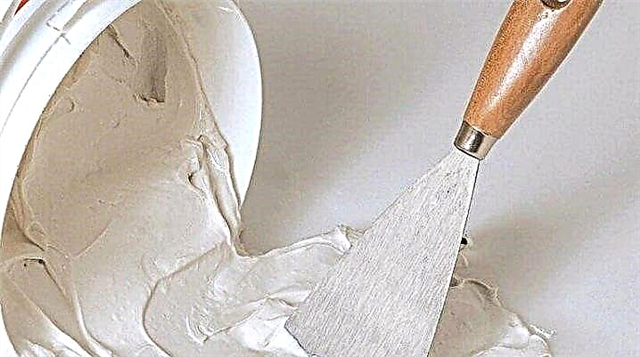

How to knead and apply a solution

To knead the solution, it is recommended to assemble a plastic container with a smooth inner surface. Water is poured there, and then a dry mixture is poured. This sequence must be observed, because otherwise you will have to fight with lumps. A small amount of the mixture must be stirred manually. But to cope with a large volume is possible only with the help of a mixer.

The amount of solution is calculated from the amount of work that you plan to complete in an hour and a half. Putty is kneaded twice. After falling asleep, the mixture is mixed with a mixer until the dry lumps get wet. The solution is then left for 5 minutes, then the procedure is repeated. These simple manipulations allow the mixture to ripen.

Features

Putty "Prospectors" - a domestic product with European quality. The recipe for the preparation of leveling mixtures is based on time-tested standards in combination with the latest modern developments.

Modern putties of this manufacturer have the following specifications:

- operating temperature - from +5 to + 30 ° С,

- consumption (with a layer thickness of 1 mm) - 1.1 kg / m2,

- mixing ratio - 0.3-0.36 l / kg,

- the viability of the diluted mixture is from 1.5 to 24 hours (depending on the type of solution),

- adhesion - not less than 0.25 MPa,

- frost resistance - 30-35 cycles.

Indicators may vary slightly depending on the type of mixture, but always meet the highest requirements and standards.

The composition of putty from the "Prospectors" (also depending on the variety) includes:

- ordinary or most often white cement,

- natural fillers

- polymer and modifying additives,

- reinforcing fibers

- antiseptic.

Due to its composition, putties of this manufacturer are different:

- Ductility. They are easily applied with a uniform and thin layer on the surface of the base. In this case, the solutions "do not slip" and do not form roughnesses.

- Good adhesion to unprimed surfaces.

- Water resistant. This is possible due to the fact that when dried putty does not form pores.

- Environmental friendliness. The material is completely safe and does not emit toxins even when heated and burned.

- Universality. It can be used both for interior decoration and for leveling facade walls. She perfectly lays on the basis of stone, wood, brick and other materials.

- Resistance to external negative factors, including natural phenomena and ultraviolet.

- The ability to dry quickly. At t about 20 ° С putty dries no longer than a day.

Moreover, even a thick layer of material does not crack after drying and does not shrink. Due to this feature, it can be used to align significant flaws and drops on the walls.

In addition, such putty is easy to grind, after which a perfectly smooth surface is obtained.

The composition is implemented in durable craft bags of 20 kg, 5 kg packages or in plastic buckets of 7 and 15 kg. In buckets, the putty is ready-made, in bags it is in the form of a dry powder, which must be diluted with water according to the instructions. The shelf life of the mixture is 12 months from the date of manufacture.

Types of putty and their composition

Currently, the market offers a wide variety of putty mixes "Prospectors", which experts are divided into several categories:

In each category there are several options for mixtures, which allows you to choose the most suitable option for each individual case.

To date, the assortment of "Prospectors" includes:

"Putty superfinishing"

The finished composition is white, based on polymer binders and fillers of fine grinding (fraction up to 60 microns). As additives, reinforcing fibers, modifying additives and antiseptic substances are used.

Such putty can be used in interior rooms with normal humidity. It is applied to walls and shelves, coated with gypsum plaster, drywall or fiberglass.

It forms a flat surface on which a paint coating or wallpaper can be applied.

“The mixture is front and finish”

Cement putty, supplemented with natural filler and all kinds of modifying additives.

Suitable for exterior and interior use in rooms with different humidity with concrete and reinforced concrete surfaces. Evenly applied on plastered walls and ceilings.

It can be used for painting, decorative plaster, various types of wallpaper.

“Facade”

Consists of white cement in combination with modifying additives. It has a light beige color.

White facade putty designed for indoor and outdoor use and can smooth the surfaces of various concrete bases (aerated concrete, foam concrete and others), used on masonry and cement plaster.

It has high frost resistance - up to 50 cycles and is applied with a layer of up to 10 mm.

As a variety of this type of mixture in the assortment of the company gray facade putty is presented.The latter differs exclusively in color - in all other respects these types of building materials are identical.

Base white and base gray

For a variant of the mixture, which includes cement and all kinds of chemical additives that give the putty improved characteristics.

It is used for finishing facades and interior spaces with any degree of humidity. Equally easily and accurately lays on plaster, brick, concrete, reinforced concrete and cellular concrete blocks. Suitable for leveling vertical and horizontal surfaces for almost any finish.

“Finishing - quick-hardening leveling mixture”

Consisting of gypsum and modified additives. It is used in interior rooms with ceilings and walls made of concrete, concrete reinforced concrete, drywall, as well as on gypsum and cement plasters.

Not suitable for rooms with high humidity.

“Finishing KR”

Finely dispersed natural filler in combination with modern polymer additives allows the use of putty for interior walls and ceilings in rooms with normal humidity. It is best placed on gypsum plasterboard and gypsum plaster, however it can be used on concrete and reinforced concrete substrates.

As a finish on this coating, you can apply texture and subtle wallpaper or paint.

“Finish Plus moisture resistant”

A polymer-cement version of the leveling mixture, which forms an even coating with a thickness of 0.3 to 3 mm. It is used both outdoors and in rooms of any degree of humidity. Provides high quality alignment of concrete and drywall walls, as well as gypsum plasterboard surfaces.

"Plaster leveling"

It is used for the preparation of concrete, brick or plastered walls and ceilings for painting and pasting. With its help, you can easily close joints between gypsum plasterboard, scratches and cracks on drywall, fill the seams of precast concrete structures and elements.

In a number of putties from the company "Starateli" there is a finished composition based on PVA in packages of 15 kg. Such a composition is suitable for any surfaces prepared for gluing or painting. It can only be used in indoor dry rooms.

Cooking and application technique

Before you putty the base, it must be thoroughly dried and prepared. You should not even try to put putty on old paint or wallpaper - such a repair will not last long. In order for everything to be done efficiently and without unnecessary losses (both time and finances), it is necessary to strip off all the old finishes. After that, the base is cleaned of dirt, dust and degreased. Walls and ceilings made of highly absorbent materials must be primed further.

No matter how high-quality leveling mixtures are, the final quality of work depends on the correctness of their preparation and application. The main rule here is to observe the clear proportions indicated by the manufacturer and the kneading technique.

Professionals recommend diluting the compositions in cylindrical plastic containers with a smooth inner surface (buckets are well suited for this). It will be easy to wash such a container before breeding the next batch of putty in it.

Small amounts of leveling solution can be mixed manually. However, using a mixer will be much more efficient. Especially when it comes to large volumes, which are unlikely to be prevented without special equipment.

When kneading, the dry mixture is poured into water, but not vice versa!

The amount of solution should be calculated based on the amount of work that the repairman will have time to complete in an hour and a half.

Important! Putty should be mixed twice. The first time it is mixed, when the dry mixture is poured into water. It is necessary to mix everything so that all dry lumps get wet well. After this, the composition is left for 3-5 minutes, and then mixed again.

Another important point is the application technique. This is especially true for beginners who do not have experience with putty mixtures.

Everything will be much simpler if you adhere to certain rules:

- In the work it is necessary to use two spatulas, one - for the collection of the mixture, the other - for the main work on the distribution of putty. To capture the composition from the tank, a narrow tool with a width of 80-100 mm is used. As for the wide spatula, its size should correspond to the area of the putty surface.

- In order for the mixture to lie as evenly as possible, it is necessary to choose the right combination of putty density, tilt angle of the working tool and pressing force.

- Most putty mixtures are applied in two layers. In this case, the second is put only after the first has dried. At normal humidity, the drying process takes up to 24 hours. Before re-applying the putty, the surface should be re-primed.

After all work is completed, you need to polish the walls (ceiling) and you can proceed to the finish.

Reviews

The high quality of the putty mixes from the company “Starateli” is indicated by numerous positive reviews of professional construction masters and those who, without building skills, independently made repairs.

Buyers note the optimal combination of price and quality. This is very important, given that in addition to putty for repair, it is necessary to purchase a large number of various building materials. In addition, professionals note that when the powders are diluted with water, they do not form dry lumps, cement particles are not felt in them and do not interfere with the creation of even coatings.

Those who undertake repairs for the first time give preference to ready putties and note their easy application, which makes it possible to significantly reduce the time for repair work.

In this video, you will find a master class on the cultivation of putty "Prospectors".

"Superfinishing" - ready putty for interior work

The composition of this material includes binder polymer components, fine fraction fillers, modifying and antiseptic additives, reinforcing fiber.

| Colour | white |

| The appearance of the coating | smooth surface without pores, sinks or cracks |

| Layer thickness | up to 2 mm |

| Middle fraction | 60 microns |

| Adhesion (not less) | 0.5 MPa |

| Drying time at a layer thickness of 1 mm, a temperature of 20 ± 2 ° C and a relative humidity of 60% | no more than 4 hours |

| Consumption during application "on sdir" Consumption with a layer thickness of 0.3 mm | from 0.3 kg / m 2 0.5 kg / m 2 |

| Frost resistance | 10 cycles |

| Shelf life | 12 months |

Putty is designed to prepare the base for finishing. The composition is suitable for internal use, provides high adhesion with almost any base, including drywall, tongue-and-groove plates, fiberglass. After application, a vapor-tight and water-repellent smooth layer of a snow-white color is created on the surface.

Application technology

The material is applied with a spatula on a dry, prepared surface. The next layer is applied only after the previous one has completely dried. The approximate time interval between application of the layers is 4 hours. To putty well laid, it is recommended to observe the temperature range. Work is carried out at a temperature + 10 / + 30 degrees, upon completion, the day should be maintained temperature +5.

GKL seams are filled with putty, a reinforcing tape is glued on top. Excess material is removed with a spatula. When the material inside the seam dries up, subsequent layers are applied to even the seam with the surface of the drywall sheet. It should be noted that the attachment points are also putty.

“Facade-finishing” - for facade and interior work

Hard putty is intended for external and internal works in the conditions of the increased and normal humidity. Suitable for walls and ceilings, fits well on concrete substrates and cement plaster.

| Colour | white |

| Mixing ratio | 0.32–0.40 L / kg (6.4–8.0 L per 20 kg) |

| Layer thickness | 0.3-3.0 mm |

| Consumption (with a layer thickness of 1 mm) | 1,0 kg / m² |

| Viability, not less | 3 h |

| Frost resistance, not less | 35 cycles |

Suitable for finishing facades, interior wall structures and ceilings. The material is used for all categories of construction projects. It should be noted that the putty is not used for the preparation of surfaces that have direct contact with food and drinking water.

Preparatory work

The base is cleaned of impurities, paintwork and oil stains are necessarily removed. Gypsum and moisture-absorbing substrates must be primed.

How to breed

The putty is mixed manually using a construction spatula. If necessary, water is fractionally added to the composition to achieve the optimum consistency for application. It should be noted that the amount of liquid should not exceed 5% by weight of the mixture.

Application technology

The material is applied with a spatula on a dry, prepared surface. The next layer is applied only after the previous one has completely dried. The approximate time interval between application of the layers is 4 hours. To putty well laid, it is recommended to observe the temperature range. Work is carried out at a temperature + 10 / + 30 degrees, upon completion, the day should be maintained temperature +5.

GKL seams are filled with putty, a reinforcing tape is glued on top. Excess material is removed with a spatula. When the material inside the seam dries up, subsequent layers are applied to even the seam with the surface of the drywall sheet. It should be noted that the attachment points are also putty.

Storage Features

Material is stored in sealed packaging at temperatures + 5 / + 35 degrees. Putty is designed for 10 cycles freezing without loss of original properties. When the material freezes, it is thawed at room temperature, mixed thoroughly. Putty can not be exposed to prolonged exposure to direct sunlight, store in the immediate vicinity of electric heaters. Storage Time - 1 year from the day of production.

“Facade-finishing” - for facade and interior work

Hard putty is intended for external and internal works in the conditions of the increased and normal humidity. Suitable for walls and ceilings, fits well on concrete substrates and cement plaster.

| Colour | white |

| Mixing ratio | 0.32–0.40 L / kg (6.4–8.0 L per 20 kg) |

| Layer thickness | 0.3-3.0 mm |

| Consumption (with a layer thickness of 1 mm) | 1,0 kg / m² |

| Viability, not less | 3 h |

| Frost resistance, not less | 35 cycles |

Suitable for finishing facades, interior wall structures and ceilings. The material is used for all categories of construction projects. It should be noted that the putty is not used for the preparation of surfaces that have direct contact with food and drinking water.

Preparatory work

The base is cleaned of dust, paintwork and oil stains are removed. Weak surfaces that can crumble are cleaned with a metal brush, moisture-absorbing ones are primed.

Proportions for the solution

The mixture is diluted in the following proportion: add per kilogram of dry composition 300-400 grams water. On the 20 kg bag will need order 8 liters of fluid. Mix the putty for 5 minutesusing a drill with a nozzle until a homogeneous creamy mass is obtained. The finished solution remains viable for 3 hours.

How to apply

First, all cracks and irregularities are filled, then the main surface, which is leveled with a thin layer, is puttyed. The material is optimally suited for mechanical application, does not need additional grinding. Work is carried out at a temperature + 10 / + 30 degrees. Finishing of the surface is carried out immediately after the putty hardens.

“Finish” - non-shrink material for dry rooms

Plastic white plaster on a gypsum base, designed for interior use.

| Colour | white |

| Mixing ratio | 0.4-0.58 L of water per 1 kg |

| Layer thickness | 0.3–5.0 mm |

| Consumption (with a layer thickness of 1 mm) | 0.9 kg / m² |

| Viability, not less | 1 hour |

Used to prepare the base for staining or wallpapering. Suitable for wall structures and ceilings made of brick and concrete. It can be used for plastering rooms where wet sanitation is provided. Important! Must not come in contact with surfaces that come into contact with food or drinking water.

Solution according to manufacturer's recommendations

Putty is bred, observing the following ratio: add per kilogram of dry material 400-580 grams water. A bag of dry mix will require an order 11.6 liters liquids. The composition is mixed with a drill until a homogeneous mass is obtained. Putty remains viable for 60 minutes.

Putty application

At the initial stage of work, putty and irregularities are filled with putty, then the main surface is treated. For application, plaster stations can be used. After drying, the composition forms a perfectly smooth surface, which eliminates the need for grinding. The time of complete drying of the material is a day at a temperature +20 degrees and good ventilation.

Packing

Putty is available in 20-kilogram kraft bags. It is stored in dry rooms on pallets.

“Finish” - non-shrink material for dry rooms

Plastic white plaster on a gypsum base, designed for interior use.

| Colour | white |

| Mixing ratio | 0.4-0.58 L of water per 1 kg |

| Layer thickness | 0.3–5.0 mm |

| Consumption (with a layer thickness of 1 mm) | 0.9 kg / m² |

| Viability, not less | 1 hour |

Used to prepare the base for staining or wallpapering. Suitable for wall structures and ceilings made of brick and concrete. It can be used for plastering rooms where wet sanitation is provided. Important! Must not come in contact with surfaces that come into contact with food or drinking water.

Preparatory work

Putty is applied only on dry substrates, cleaned of all contaminants. Weak-resistant surfaces prone to shedding are removed with metal brushes, moisture-absorbing ones are primed.

Solution according to manufacturer's recommendations

Putty is bred, observing the following ratio: add per kilogram of dry material 400-580 grams water. A bag of dry mix will require an order 11.6 liters liquids. The composition is mixed with a drill until a homogeneous mass is obtained. Putty remains viable for 60 minutes.

How to apply

At the initial stage, hollows and bumps are filled, then the main surface is putty. Work performed at temperature +10/+30 degrees, putty does not require additional alignment after application. When applying the next layer, the surface of the previous one is primed.

What packaging can I buy

Putty is available in bags, in bulk 5, 12, 20 kilogram. Store the material in a dry place on wooden pallets, in undamaged containers. Shelf life - 12 months from the date of manufacture.

“Finishing KR” - a perfectly smooth surface

A polymer-based plastic mixture designed for work in dry rooms.

| Colour | white |

| Mixing ratio | 0.3–0.4 l / kg (6–8 l per 20 kg) |

| Layer thickness | 0.3–3 mm |

| Mixture consumption with a layer of 1 mm | 1.1 kg / m² |

| Viability, not less | 24 h |

It is used to align the interior walls and ceilings of dry rooms. Suitable for rooms where wet sanitation is provided. Putty creates a perfectly even base of white color, which helps to prepare the surface for painting.Due to its properties, “Finishing KR” is optimally suited for ceilings and wall structures made of drywall.

Preparatory work

The base is cleaned of all kinds of contaminants, surfaces with enhanced moisture-absorbing properties are primed.

How to prepare a solution

Putty is mixed in the following proportion: a kilogram of dry material per 300-400 gram of water. On the 20- a kilogram bag of dry mix will need about 8 liters liquids. The mixture is stirred with a drill to get a uniform mass.

Putty application

At the initial stage of work, putty and irregularities are filled with putty, then the main surface is treated. For application, plaster stations can be used. After drying, the composition forms a perfectly smooth surface, which eliminates the need for grinding. The time of complete drying of the material is a day at a temperature +20 degrees and good ventilation.

Packing

The mixture is sold in bulk bags. 5 and 20 kg, which is recommended to be stored on pallets, in rooms with moderate humidity. Shelf life - 12 months while maintaining the integrity of the package.

“Finish Plus” Moisture-resistant - cement-polymer mixture for dry and wet rooms

A plastic, moisture-resistant mixture on a polymer basis, prepares the surface for coloring, pasting with thin and textured wallpaper.

| Colour | white |

| The appearance of the coating | smooth surface without pores, sinks or cracks |

| Layer thickness | up to 2 mm |

| Middle fraction | 60 microns |

| Adhesion (not less) | 0.5 MPa |

| Drying time at a layer thickness of 1 mm, a temperature of 20 ± 2 ° C and a relative humidity of 60% | no more than 4 hours |

| Consumption during application "on sdir" Consumption with a layer thickness of 0.3 mm | from 0.3 kg / m 2 0.5 kg / m 2 |

| Frost resistance | 10 cycles |

| Shelf life | 12 months |

Suitable for the preparation of surfaces coated with cement or lime-cement mortar, GLK ceilings. Putty is not afraid of high humidity, it is used for finishing all types of construction projects. Important! The material must not come in contact with surfaces that come into contact with drinking water and food.

How to prepare a solution

Putty is mixed in the following proportion: a kilogram of dry material per 300-400 gram of water. On the 20- a kilogram bag of dry mix will need about 8 liters liquids. The mixture is stirred with a drill to get a uniform mass.

Putty application

At the initial stage of work, putty and irregularities are filled with putty, then the main surface is treated. For application, plaster stations can be used. After drying, the composition forms a perfectly smooth surface, which eliminates the need for grinding. The time of complete drying of the material is a day at a temperature +20 degrees and good ventilation.

Packing

The mixture is sold in bulk bags. 5 and 20 kg, which is recommended to be stored on pallets, in rooms with moderate humidity. Shelf life - 12 months while maintaining the integrity of the package.

“Finish Plus” Moisture-resistant - cement-polymer mixture for dry and wet rooms

A plastic, moisture-resistant mixture on a polymer basis, prepares the surface for coloring, pasting with thin and textured wallpaper.

| Colour | white |

| The appearance of the coating | smooth surface without pores, sinks or cracks |

| Layer thickness | up to 2 mm |

| Middle fraction | 60 microns |

| Adhesion (not less) | 0.5 MPa |

| Drying time at a layer thickness of 1 mm, a temperature of 20 ± 2 ° C and a relative humidity of 60% | no more than 4 hours |

| Consumption during application "on sdir" Consumption with a layer thickness of 0.3 mm | from 0.3 kg / m 2 0.5 kg / m 2 |

| Frost resistance | 10 cycles |

| Shelf life | 12 months |

Suitable for the preparation of surfaces coated with cement or lime-cement mortar, GLK ceilings. Putty is not afraid of high humidity, it is used for finishing all types of construction projects. Important! The material must not come in contact with surfaces that come into contact with drinking water and food.

Preparatory work

Weak surfaces prone to shedding are treated with a wire brush. The base is protected from any contamination. If the surface has the ability to absorb moisture, it is necessary to apply a primer coat.

How to prepare a solution

The material is prepared according to this scheme: add per kilogram of dry mixture 350-400 gram of water. A bag of mixture will take about 8 liters of water. The solution remains viable for 4 hours.

A few words about the manufacturer

The history of the company "Prospectors" began in 1992. The company was initially focused on the production of ready-made putties, subsequently, the range of products began to expand. IN 90s years of the last century, this direction of the construction market was not yet developed, so I had to use the experience of European manufacturers. The company learned from the mistakes of others, introducing its own technologies and implementing a computerized quality control system.

Currently, the company operates according to its own recipe, using only high-quality raw materials. This helped Starateli to become the largest manufacturer and supplier of ready-made dry mixes.

Prospectors' independent putty reviews

We have collected for you real user reviews from major forums and thematic sites. Take a look:

Sergei. Very convenient putty for work.

The fine-grained mixture is perfectly mixed, easily turning into a homogeneous substance. The composition is convenient to apply: it lays in a thin layer, while filling any irregularities and cracks. The main advantage is considered an affordable price with high quality material. No flaws were identified.

Novel. I have been using Prospectors putty for a long time.

Therefore, I was able to form a definite opinion about the material. Initially, it was a budget option for interior decoration. The quality of the mixture was maintained at a high level. Putty is convenient in stirring and application, but differs in surprising fragility: after 1.5-2 years cracks begin to appear, the surface begins to crumble.

Elina. Used to decorate the children's room in the apartment.

There are no complaints about the composition: reasonable price, convenient application, good ductility and a long time to maintain viability. However, the coating is easily scratched, but this is the only identified drawback.

Oleg. I have been engaged in construction for a long time, and I'm used to mistrusting cheap materials.

Putty "Prospectors" also initially aroused doubts, but having tried the mixture in practice, I realized that this was just the perfect option. Convenient packaging, good ductility, white color, flat surface. The only limitation is that it cannot be used for decorating kitchen facilities and bathrooms. In general, there are no complaints, so I will continue to work with products from this manufacturer.

Konstantin. I made repairs in the apartment with my own hands.

I am not a great specialist in the field of construction, so I bought several dry mixes for testing. Putty "Prospectors" pleasantly surprised by the ease of use, despite the fact that it was the cheapest mixture of purchased. I did not like that when stirring, lumps are formed that dissolve only after 5-10 minutes.