The foundation is the foundation of any building. It has a direct impact on the quality and reliability of the building as a whole. Do you want your bath to be strong and serve you for many years? Make a quality foundation!

The basis for the structure can be of different types: there is a foundation for a bathhouse columnar, strip. There are other types, but usually during construction they choose between these two options.

The strip foundation is the most popular option, which is more reliable than the columnar one, but its construction requires a lot of effort and time.

Strip foundation for the bath: advantages

- ability to withstand high loads. A strip foundation can support the weight of even buildings that have several floors,

- easy installation. To build this type of foundation, you don’t need to use special equipment and sophisticated technologies,

- speed of construction. If you use ready-made concrete, then the construction of the foundation will take a week, and if you yourself - less than a month,

- reasonably low price. The strip foundation for a bath usually has compact dimensions, so to create it does not require a lot of material. During construction, cheap raw materials are used: concrete, reinforcement, boards and rubble,

- the possibility of subsequently making a cellar or basement,

- universality. A similar type of foundation can be used in the construction of a bath of timber, aerated concrete and even brick.

Strip foundation for the bath: disadvantages

- a lot of weight. Concrete is a heavy material, so if you choose the wrong place for construction, you may encounter the fact that the building will sag on one side,

- the need for a thorough study of the soil and the calculation of the depth. The depth of the strip foundation under the bath is directly dependent on the soil. If the foundation is made too shallow, then the building may sag and deform,

- the impossibility of building on the ground with a weak bearing capacity.

Do-it-yourself strip foundation under the bathhouse: types and their features

This type of foundation can be of several types. If we consider its types by device, then there are two types: monolithic, prefabricated and monolithic prefabricated.

A feature of the monolithic foundation is that when it is erected, a reinforced formwork trench is made into which concrete mortar is poured. Prefabricated base involves the assembly of prefabricated reinforced concrete blocks of factory production.

Currently, there is also a precast-monolithic technology, which includes two types of foundation devices: part of the base is made of reinforced concrete, and the other of the blocks.

Depending on the depth, the foundation can also be of several types: not deep or deep.

Shallow strip foundation for a bath is the best option for small and light baths, for example, made of wood. It can be laid on sand and clay. Its advantage is its shallow depth (about 0.5 m), which makes building materials less necessary for its construction, which leads to significant savings.

A recessed strip foundation is a high-quality and reliable foundation, ideally suited for the construction of large and massive baths, as well as two-story baths combined with a house, etc. But note that this type of foundation will require large financial expenses, and it is much more difficult to install .

Depending on the material that was chosen for the construction, the foundation can be:

- brick,

- rubble,

- sandy,

- soil cement

- reinforced concrete.

The most reliable foundation is recognized from concrete.Large stones weigh about 30 kg and have a length of about 0.3 m. They are quite inexpensive. This foundation is easy to do with your own hands. If the soil is sandy and rocky, rubble foundation will not work, as it can crack quickly.

The brick foundation is also widespread, but its peculiarity is that the brick is a hygroscopic material, therefore, the foundation cannot be made at a great depth or near groundwater. The brick base is suitable for dry sandy soil. Only red brick is used for the foundation, since it is less susceptible to water.

Sandy and soil-cement foundations are suitable only for the construction of light non-residential premises on a solid foundation.

Reinforced concrete foundation is a cheap, but at the same time quite durable type of foundation, which is also suitable for complex baths. To raise this material you need to use a special technique. With your own hands, you can make a foundation using blocks measuring 20x20x40 cm.

More information about the features and types of the strip foundation of the bath in the video:

What brand of concrete for a strip foundation for a bath is better?

Of course, the foundation of reliability of the foundation is the use of high-quality material. When choosing a concrete brand, you need to focus on the total weight of the bath, type of reinforcement and soil.

If you are planning to build a small and light structure, for example, a frame bath on a strip foundation, then concrete of grade 200 is suitable for you. If the structure is heavy, but not too bulky, it is better to choose grades 250 or 300.

For the construction of heavy and massive structures will need concrete grade 350.

Also pay attention to the quality of the soil. If it is strong and dense enough, then concrete grades 200 or 250 are suitable. For shaky and heaving soil, use better concrete - from 300.kr

The higher the grade of concrete, the higher the quality and cost. It is not recommended to save on concrete, since a poor-quality foundation will lead to a significant reduction in the service life of the entire building and its premature destruction.

Stage 1. Preparation of the territory

It is necessary to clear the area on which construction work will take place from garbage, stones, trees and shrubs. If grass grows in the area, it is recommended to remove the top layer.

It is not necessary to clean the site itself exactly on which the building will be erected, but the territory is slightly larger (at least 1 m on each side).

Stage 2. Laying out the foundation plan, preparing the trench

To do this, you need pegs, a square, a tape measure and twine. It is necessary to drive pegs into all corners of the future building, then pull the twine between them.

After preparing all the points, you can proceed to digging the trench.

The dimensions of the strip foundation under the bathhouse may vary depending on the planned construction and the type of soil. When choosing the depth of the trench, you need to focus on climatic conditions. The height of the strip foundation for the bath is usually 0.5-0.7 m.

For fine sandy soil and non-porous clay soil, characterized by high hardness, a trench with a depth of half a meter with a freezing depth of up to a meter, 0.75-1 m - with 1.5-2 m will be enough. For a sandy soil, the trench should be at least 0.6 m and above the freezing depth. For heaving soil, a trench should be prepared to the depth of freezing.

The width of the strip foundation of the bath directly depends on the width of future walls. It should be about 0.5-1 m. But if the soil is weak, then its increase to 2-2.5 m is permissible. Accordingly, the trench itself should be slightly larger (about 0.2 m) than the width of the foundation.

In addition, the width of the foundation passing under the internal partitions is usually made 0.1 m less than under the external walls.

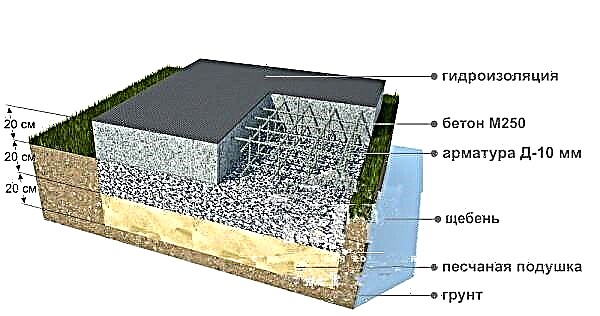

The bottom of the prepared trench should be covered with a sand cushion, its thickness should be 0.1-0.2 m.First, pour a layer of sand into the trench, then pour it with water and ram it, and then cover it with gravel, then level it again.

A pillow is needed to prevent distortions and deformation of the building. In addition, a layer of sand protects the foundation from sudden temperature changes during periods of rain and snow.

Stage 3. Formwork for the foundation

Formwork is a frame that will set the shape for the future foundation. For it, you need to use boards with a thickness of at least 30 mm or chipboard 20-22 mm. The height of the formwork should be at least 30 cm, it is necessary that it exceed the height of the future foundation.

It happens that the formwork is left and used as additional thermal insulation. In this case, its height should be equal to the height of the foundation itself.

To install the formwork, you need to install supports on the edges of the trench and attach the walls of the structure to them. It is important that the inner surface of the frame is as even as possible.

So that when pouring concrete the solution does not fall into the cracks, it is recommended to cover the formwork with a film or a layer of roofing material.

Below is the video: Do-it-yourself tape foundation of the bath. Formwork:

Stage 4. Reinforcement of formwork

Despite the fact that concrete itself is a strong and reliable material, it must be taken into account that the load on it will be enormous. In addition, concrete is completely non-plastic, so reinforcement should be done. Such a reinforcement will help protect it from destruction.

For reinforcement, fittings with a diameter of 1.2-1.6 mm that have passed anti-corrosion treatment are suitable. In the bottom of the trench you need to drive in two rows of reinforcement segments. A gap of 5 cm must be left between them and the walls of the formwork, it is important that the segments are lower than the foundation by about 5 cm.

After that, put the rods at the bottom and tie them with wire to the vertical supports at a distance of 7-10 cm from the bottom. Under the bars you can also put broken bricks. The top row of reinforcement should be below the foundation level by approximately 7 cm.

If you are making a strip foundation for a bath with a drain, then just at this stage you need to take care of communications. It is recommended to make them underground. To prepare the technological holes, it will be necessary to cut off part of the plastic pipe and attach it to the fittings in the right place.

Stage 5. Pouring the foundation

To fill the strip foundation under the bath, you can prepare the mixture yourself or buy a finished one. The advantage of the latter option is to reduce work and reduce the time to prepare the foundation for the bath.

Then you need to remove all excess air from the concrete to make it more dense. To do this, it is necessary to level it and pierce with a bayonet shovel. For the same purpose, formwork from the outside must be tapped with a hammer.

If the weather is hot outside, then you need to water the foundation at least a couple of times a day, if on the contrary, it rains constantly, then cover the base with foil.

After 3 days, the formwork can be removed. The erection of the walls of the bath can only begin 3 weeks after the erection of the foundation.

Now you know how to make a strip foundation for a bathhouse. This option base has many advantages. It is quite versatile and suitable not only for small buildings, but also for multi-storey buildings.

Do not save on the foundation, if it is strong and reliable, then the bath will serve you for many years!

Features of the soil that should be considered when building a foundation

The soil in the area where the bath will be built must meet certain requirements in order to avoid subsequent subsidence of the foundation and the entire structure. For example, soil based on peat, silt or fine sand is completely unsuitable for this purpose: it is prone to swelling, creeping and uneven liquefaction.

Sometimes, in such cases, a coarse sand cushion is a good way out.To do this, dig a trench corresponding to the size of the foundation, lay the bottom with coarse-grained sand, watered with water and carefully tamped.

Of course, a homogeneous, dry soil with good density is ideal for foundations.. But not every owner can boast of such a wonderful site. In the case of heterogeneous soil with high humidity, the foundation foundation should be dug to a depth of half a meter or more. The fact is that during winter frosts, soil with high humidity, freezing, will raise the foundation, and in summer, after melting and drying, it will lower. From this wall can "tune up" and give cracks. To avoid this, you should find out the depth of soil freezing, and during construction, lay the foundation 20 centimeters below this level.

The most common types of foundations used in the construction of baths

Usually in our latitudes for a traditional Russian bath, a columnar, strip or slab foundation is preferred. These types of foundations are quite simple in construction and reliable in operation. In addition, it is easy to find materials for them in any construction supermarket.

When choosing the type of foundation should, first of all, be guided by the type of soil in the area where the bathhouse is being built. For example, a columnar foundation is usually installed on clay or loamy soil with a deep occurrence of groundwater. The advantages of a columnar foundation are especially noticeable when building block, framed or chopped baths, in such cases additional jumpers between the columns are not required. Loose, poor-bearing soil is not suitable for this type of foundation, and the use of heavy materials in the construction is not recommended.

The strip foundation is usually used in the construction of small structures. The structure of this base includes reinforced concrete blocks and rubble stones bonded to each other. Depending on the type of construction and the size of the log house under construction, the width of the foundation is calculated. The strip foundation is quite simple in design, but it will require high labor costs, a large number of works and materials used in the construction.

The slab foundation (it is also called monolithic) is considered by many to be the most reliable. It is the best option if the soil in the building plot is weak and prone to swelling. In addition, when erecting the walls of a log house, using a monolithic slab as a foundation, you eliminate the need to fix the wall in a certain area of the base. On the contrary, the walls can be moved as you see fit, and besides, they can all be load-bearing. The slab foundation will protect the bath from the penetration of rodents and insects and will not require expensive waterproofing.

Each of these types of foundations requires a careful approach to the construction, so we will consider them in detail separately.

Building a foundation of a columnar view

Installation of the foundation begins with a breakdown of the site allocated for the construction of the bath, according to the plan. At the same time, the use of the Egyptian triangle with sides 3 X 4 X 5 will be optimal. This will help to correctly set the right angles of the base. It is easy to make such a triangle yourself from improvised means: boards and ropes. Correctness of the angles is checked by measuring and comparing the diagonals.

The recommended distance between the installed poles should not exceed 2.5 meters. The materials used in their construction are concrete, reinforced concrete, brick or stone. In places where the inner and outer walls are joined together, the posts are placed at an angle of construction. In such cases, the gaps between the posts may exceed 2.5 meters, so you will need to install additional supports. The standard cross-section of the pillars for the foundation for the construction of the bath is 50-60 cm, but it can be made smaller if you are building a light-weight bath.

A simple bath can be installed not on stone, but on wooden poles, popularly called chairs. This version of the foundation for the bath will be much cheaper. The principle of the arrangement of such pillars is no different from the installation of stone or concrete fortifications.

The depth is calculated at which wooden poles should be dug, based on the depth of freezing of the soil. To it is added about 25 centimeters.

Before walled up the chairs in the ground, they should be thoroughly dried and treated with antiseptics. In order to reduce the impact of external factors on wooden poles, they are wrapped in waterproof material, for example, roofing material or a polyethylene film, and coated with tar.

When erecting concrete and brick supports used as the basis for a columnar foundation under a bath, special attention should be paid to the fact that they do not withstand tensile deformation. To prevent it, the pillars should be built strictly vertically: this will help to avoid eccentric impact. During construction, the cross section of the pillars is recommended to be overestimated.

Column foundation on drill piles

In modern construction of bathhouses, do-it-yourselfers increasingly use a columnar foundation based on drill piles. Such piles are quick and easy to build. For such a foundation you will need:

You will spend no more than 30 minutes on drilling a well with a depth of about one and a half meters.

If the soil on the site has standard bearing characteristics, then the diameter of the well is up to 25 centimeters. An asbestos-cement pipe 20 cm in diameter is placed in the well, the gaps on the sides are filled with sand and concrete mortar for leveling. The solution also fills the pipe from the inside.

The next step is raising the pipe to the height set according to the design. At the same time, a certain amount of concrete mixture will come out of it, which will become the basis for the pile. If necessary, the solution is added inside the pipe, while 10-15 cm should remain to the upper level. After the mixture is compacted inside and out, fittings are inserted into it.

Using this technology, make the required number of posts. In the summer, in the heat, such a support will dry for no more than a week. When it rains, cover it with plastic wrap to prevent water from entering.

The column foundation for the bath is ready. Now you can start building walls.

Building the foundation of the tape view

The strip foundation under the bath is a continuous reinforced concrete strip around the perimeter, practically not buried in the ground. The depth at which the base of the foundation will be located is calculated based on the characteristics of the soil: dry and sandy soil allows you to raise the sole 50-60 cm above the freezing level, wet and uneven - requires installation 20-30 cm below this level.

In the case of construction on uneven ground, white fine sand will serve as a pillow for the foundation. Such a pillow consists of three identical layers. Each of them is watered and rammed. As a result, a three-layer pillow should be 30-40 cm thick.

A uniform layer of gravel about 15 cm thick is poured over the sand cushion, which in turn is poured with cement mortar. This procedure is repeated several times until the gravel poured by the solution reaches a zero level, that is, the surface of the earth. At this level, a wooden formwork is made, into which concrete is poured, and a waterproofing layer is installed. As such, it is advisable to use 2-3 layers of roofing material laid tightly on a vertical surface, and bitumen mastic.

How to make a foundation for a bath?

The answer to this question depends on what type of foundation is chosen for construction, taking into account the geology and hydrology of the site, as well as the future base load. We will briefly review the schemes of work on each type, and you will find detailed plans (what and how to do) in separate articles to which we will refer. In particular, we recommend reading:

However, the work plan has common points - they are the same and I don’t want to repeat. Before proceeding to the layout of the future bath, you need:

- remove trees, shrubs and large stones from the territory,

- cut off the fertile soil layer and transfer,

- to smooth out the irregularities of the site in the building spot - manually or using a bulldozer.

Markup - This is another general point, but the chapter below is entirely devoted to it. And now we will consider the different stages of laying for each type separately.

Pile

How to make a pile foundation for a bath. This view suggests minimal disturbance of soil integrity. On the prepared and marked site in the ground, either wells are drilled for the bored variety of the pile foundation, or iron piles are immediately screwed.

If we are talking about bored, then the well is strengthened with sand and gravel, then a casing is installed, into which the reinforcing cage is laid. After this, it remains only to pour concrete into each pipe and expel air from it.

In our article on pile foundations, you will find more information that interests you.

Tiled

Now a little about how to build a slab foundation for a bath.

- A sand and gravel cushion is poured into the finished pit with a layer of up to 30 cm.

- Formwork is placed on the cushioned pillow, a place is allocated in advance for future communications.

- After this, it is necessary to isolate the future concrete slab from moisture from the soil. To this bottom and side formwork is placed polyethylene. You can put another waterproofing material instead.

- The next step is laying a grid of rods from 8 to 12 mm thick (depending on the severity of the future building).

- Concrete is poured over the frame. After filling, it is still necessary to expel air bubbles from it.

How to calculate the foundation for a bath

Building a foundation for a bath is not an expensive business. It is possible to imagine the costs of foundation only after assessing the volumes of materials that will be needed for the selected bath size. We will show by examples how to calculate the foundation for a bath.

But first you need to calculate the total load on the ground, which will provide a ready bath. You already imagine what size and from what material you would like to build a bathhouse and you can make a calculation. Calculate the area of the roof, walls and floors, and then multiply by the data from the table. Adding the results, you get the weight of the finished structure:

| Building element | Material | Density (kg / m²) |

| Walls (150 mm thickness) | Frame + mineral wool | 30-50 |

| Bar or log house | 70-100 | |

| Brick | 200-270 | |

| Roof | Sheet steel | 20-30 |

| Ruberoid | 30-50 | |

| Slate | 40-50 | |

| Roof tiles. | 60-80 |

If the floor is reinforced concrete, then consider it as 500 kg / m².

| On wooden beams | Basement (kg / m²) | Attic (kg / m²) |

| Density up to 200 kg / m² | 100-150 | 70-100 |

| Density up to 500 kg / m² | 200-300 | 150-200 |

The scheme of calculation of the strip foundation

Previous calculations are needed in order to select the optimal tape width based on the total load and soil bearing capacity. You should learn the latest from geologists.

To get started, take the width of the foundation tape according to the rule:

The thickness of the future wall + 10 cm

After that, calculate the area of the entire foundation tape. You can divide it into rectangles, then add their area. As a result, we get the value reference area.

It remains only to divide the total mass of the bath into the reference area to find out what the pressure on the ground will be. Compare with the bearing capacity of the soil - if it is less than the pressure of the bath, it is worth revising either the design or the width of the tape. (Generally, it is undesirable that the pressure of the structure was more than 70% of the bearing capacity of the soil).

We recount until the numbers are acceptable. Now that the area of the tape is known, it will not be difficult for us to calculate its volume. Multiply the area by height.This will be the volume to be filled with concrete. Count and weight, based on the fact that 1 cube of reinforced concrete weighs 2400 kg.

An example of calculating a columnar foundation (including bored piles)

In this case, we take one kind of pillars, for example, bored piles. They have a variety that has a main diameter of 300 mm, and at the bottom expands into a shoe with a diameter of 500 mm. From here sole circle area:

S = π x r² = 3.14 x 25 x 25 = 1962.5 cm²

You need to know two more values: the total weight of the bath and the bearing capacity of the soil (soil resistance). The first is calculated from the above tables, the second is recognized by geologists after the research. Suppose that the bathhouse is frame and its weight is 23,000 kg, the bearing capacity of the soil is 2 (we remember that it is worth taking only 70% of this value).

0.7 x 2 = 23000: (1962.5 x N),

where N is the number of columns.

From here it is easy to calculate that rounded is N = 9, but this is only the first approximation. Now we need to find out the weight of 9 columns and add it to the weight of the bath. We will consider this:

Pile length - 2 m

Diameter - 0.3 m

It remains to multiply the area of the circle by the height of the cylinder to get the volume:

V = π x r² x h = 3.14 x 0.15 x 0.15 x 2 = 0.1413 m³

Accordingly, the volume of 9 piles is 1.2717 m³, which, with a mass of 1 cubic meter of reinforced concrete, 2400 kg gives 3 052 kg, which we add to 23 000 kg of the mass of the bath. Counting again:

N = 26,052: (1.4 x 1962.5) = 9.48 rounded 10 piles

It remains only to distribute them at the points of maximum load and evenly between them.

The calculation scheme of the pile foundation (here only screw)

Screw piles for foundations are 89 and 108 mm. The former are used only for light buildings, for example, wireframe. The second is for everyone else.

The simplest method of calculation is the arrangement of piles according to the plan of the bath at the corners and points of greatest load. (So it is recommended to put at least 2 piles under the stove).

Another option is to use information about the mass of the bath and divide it into the bearing capacity of one pile. Data can be obtained from the table below (this is a calculation for a pile submerged in soil at 2 m).

By the way, many sellers of piles put on their sites calculatorsthat count the number of piles for your case.

Slab foundation calculation scheme

And again, we must calculate the pressure of the bath on the ground to make sure that the structure is easier than it is able to carry out the soil without subsidence.

In the case of the slab foundation, we have a very large area over which the total load is distributed, but it is worth taking into account the fact that the stove weighs a lot.

Suppose a 4 x 4 meter bath is planned. And that we will put it on a plate 20 cm thick. Let the weight of the bath be estimated at 50 tons, and the soil resistance 2.5.

We already know that a cube of reinforced concrete weighs 2,400 kg. Then the mass of the foundation is 7680 kg. The total load is 58 tons per 16 squares or 3,625 kg per m². Soil can carry 2.5 kg per cm² or 25 tons per m². In the same way, you can calculate the load for your data.

General principles

Building a right angle - the problem can be solved "mechanically" or with the help of calculations.

Laser level BOSCH PLL 1 P

With calculations it’s easy: the square of the hypotenuse is equal to the sum of the squares of the legs, and the legs are our walls. You can simplify the case with integers: 3² + 4² = 5². For this, a Bechev 12 m is taken and its ends are connected very accurately. 3 and 4 meters are marked. It is enough to stretch the rope into a triangle so that a clear right angle is formed between the smaller sides (3 and 4).

Mechanical methods - This is either to use the square from the rails, or the laser level (the video will tell about the latter).

Anyway, it all starts from the lowest corner of the future bathwhere the first peg is hammered and a right angle with the given sides is built from it.

Then the diagonal is checked and the next right angle is built. So - until all the corners are lined up. Corner points are marked with pegs..

The next step is the marking of the internal or external circuit (depending on which you have not done yet). Corner points are also marked with pegs.

Casting is the next step in marking.

Racks of two columns with one or two crossbars are driven into the ground at a distance of 1.5-2 meters from the initial pegs (see below). it racks castoffs.

They are driven into the ground so that the edge of the crossbar is at a certain level:

- trimmed strip or slab foundation,

- the edges of the pipe, pile or column of the pile or column foundation (for foundations with grillage, two crossbars are made - the level of the column / pile and the level of the grillage).

Building threads stretched by risks on the crossbeams form the internal and external contours of the foundation in the air.

The depth of the trench or pit is counted from the castoff so that the perimeter is even regardless of the terrain.

Now we will analyze how to correctly lay out the foundation for the bath, depending on its type.

Nuances for different types of foundations

For tape The following risks are made on the crossbar:

- the axis of the wall in the center,

- the width of the foundation tape (axis in its center),

- the width of the pillow under the base.

We highly recommend watching a video that specifically talks about using the laser level when marking a strip foundation:

Pillar column or pile foundation notes:

- the height of the foundation (edge of piles or columns),

- grillage height

- axis of pillars or piles.

Corner supports are marked immediately by the intersection of threads. Intermediate supports are measured after. Axial points are lowered to the ground using a plumb line and marked with pegs.

Before drilling or digging pits, construction threads are removed.

Plate marking the easiest way, because only the borders of the slab should be noted.

When is it needed?

There are two real reasons that are not related to the horror stories about condensate, mucus and mold, which are often scared on the Internet (because ventilation copes with condensation much better than insulation).

- This desire is to reduce heat loss and time for heating the bath.

- As well as the protection of waterproofing from a violation of its integrity during the seasonal movement of freezing soil. Plus, reducing the heaving of the soil itself, if you insulate it too.

Usually, foundation insulation is typical for buildings with a basement. And baths are rarely made with a basement. Therefore, there is no urgent need for insulation.

But if you still decide to insulate the foundation of the bath, then do it outside. There are people asking how to insulate the foundation of the bath from the inside, we do not recommend this. Internal insulation is not recommended.

But if you still decide to insulate the foundation of the bath, then do it outside. There are people asking how to insulate the foundation of the bath from the inside, we do not recommend this. Internal insulation is not recommended.

As for the material, then it is better to take one whose life span is commensurate with the life span of concrete. Polyfoam in this regard is much inferior to concrete in "longevity" and a warm foundation will not be forever. Therefore, professionals recommend foam glass.

Warming the foundation of the bath can be done at the stage of laying. In this case, the width of the formwork is increased by the thickness of the insulating material.

In the case when insulation is done for the already built bath, have to:

open the foundation

- pour sand with gravel to the bottom,

- insulation can be simply glued to the walls of the foundation,

- at the end, the foundation is backfilled with soil, which must be carefully compacted.

If column foundationwill have to work even harder:

- a trench is excavated along each wall (width 0.5 m, and depth 1.5 m),

- sand and gravel are poured into the bottom of the trench, rammed,

- a wall of bricks is laid on the pillow, which is lifted almost before the start of masonry,

- the gap between the brick and the wall is foamed with mounting foam,

- bricks are oiled with bitumen mastic,

- the trench is backfilled and rammed.

Bar or log house

Consider how to put a log cabin on the foundation. To put the first (strapping) crown of a wooden bath, you must first waterproof the foundation, and soak the crowns with an antiseptic.

It is recommended to put a 50 mm thick board around the entire perimeter on the waterproofing, and only then put the first crown on it.The so-called cushioning board will contribute to the fit of the log house to the waterproofing.

Before laying logs are disassembled according to the marking.

Locks are cut in advance in logs or uneven bars. Usually the end is simply trimmed “in half a tree” - half the thickness of the crown.

The lower crown is often not attached to the foundation at all., because he and so will not shift under the weight of the bath.

Brick, foam block, cinder block

This is a group of block materials. Their laying on a strip or slab foundation is done immediately after its waterproofing. If the foundation is pile or columnar, then grillage becomes mandatory, and then everything is exactly the same as for tape or slab.

If you are just looking at the construction of a block bath, we also have an article on the foundation for a foam block bath. And another article with an overview of the options for foundations for block baths.

Frame

Usually a solid timber is used as a strapping for a future frame bath. But to his styling must be prepared at the foundation stage: studs with threads on the end should be firmly fixed to the foundation. A support beam will be worn on these studs and secured with nuts.

In a columnar or pile foundation, anchor bolts are mounted in a grillage.

The corners of the strapping beam are cut “in half the tree” and fixed with brackets and nails of 120 mm.

***

You got a fairly voluminous idea of how the foundations for a bath of various types are created. We can only wish you good luck in finding the desired.

Site preparation and layout

Construction begins with marking. We’ll need a little tool: 10 wooden stakes, a hammer, a tape measure of 15 meters long, a building cord of 25 meters, or a fishing line, a hydro level of 20 meters. Take a regular foundation made of expanded clay concrete blocks. Such a foundation for a bath with their own hands is built in a couple of days and does not require huge infusions of funds. Take the standard option.

We calculate the width of small pits. We take into account the insulation and binding of the foundation blocks of the bath: 200 mm block width, and 400 mm length. Basement height approx. 600 mm, 3 blocks. It turns out that the pits for development will be: 450 x 450 mm, with a depth of 0.8 meters - this is the standard size of the width and depth for the usual construction of a block base from expanded clay concrete blocks. Now let's move on to the development of pits.

Development of soil under the bath

To make the foundation of the bath with your own hands you will need: a shovel, bayonet, shovel, pickaxe, in case of the presence of stones, an ax for snags, and a cart for removing soil. Having dug the set depth, we precisely align all edges. The foundation for the furnace (bath stove) should also be provided. We must not forget that the device of the furnace inside the building requires the preparation of a pillow made of concrete. This is carried out before pouring the main monolith, after the calculation, a pillow is made, and then the support pits are poured under the expanded clay concrete blocks.

Pillow under the furnace or firebox

Dig a pit 1200 x 1200 mm to a depth of 600 mm. This depth is not accidental, 300 mm is poured with sand. Ram the pillow by hand tamper. The following are the steps:

- A layer of waterproofing material is laid at the bottom, so that it is with a margin, and the edges protrude outside the pit.

- Put the frame (formwork) to the required height, and pour a concrete slab of 200 mm.

- Warming is carried out with 50 mm expanded polystyrene plates, laying it directly on fresh concrete.

- Then pour the finishing layer of the screed, 50-150 mm. Insulation under the heating element is ready.

After concrete work on the installation of the bearing cushion, it is necessary to lay a network of water and sewage pipes and conduct their complete insulation.

Tip: The base under the furnace should not be in contact with the main foundation, as it has the property of expanding when heated. The gap is filled with sand after concrete work and the dismantling of the upper formwork.

Networks and drain

Let's move on to laying pipes for water supply networks. Calculation of the diameter and length of the water supply networks is carried out in advance, before the production of all concrete work. Separate trenches dig under the water supply pipes, to the pipe outlet points. The installation of water supply networks requires special skills and knowledge, but the preparation of trenches can be carried out independently. According to technology, pipes are laid on a pillow of crushed stone. The filling of the bottom of the ditches is equipped with gravel, the thickness of the standard layer is 80-100 mm. The ends of the pipes are displayed 100 mm above the floor, in the right place and are closed with plugs.

Subsequently, after all concrete work and the construction of the walls of the sleepers, all pipes and internal networks are installed. The depth of laying pipes into the ground from the outside of the room is 1200 mm, and from the inside 600 mm. Networking can be carried out simultaneously with the drain, laying pipes together.

A pillow for laying pipes and networks is rammed without fail. The slope is measured for laying sewer pipes, the height of the inlet and outlet openings, the drain angle. Before you make the whole foundation for a bath, take a drain for wastewater. Prepare a pit or pit, drain there. The optimal distance between the bath and the drain is 6-10 meters, otherwise the log house will damp.

Foundation insulation

The foundation for the frame bath can freeze, therefore, it is insulated from the outside with various materials. Warming is carried out before pouring concrete. Apply a sheet of foam or polystyrene, for these purposes they are optimally suited. Apply sheets with a thickness of 50 - 80 mm., With a size of 600 x 1000 or 1000 x 1000 mm.

They are fastened on the outside of the pits (on the outer edge), between the armature frame and the ground. Then the space is completely poured with concrete to the required height. Warming is obtained with high-quality and monolithic, durable. Expanded polystyrene does not absorb moisture. The service life of such materials is 25-30 years.

There is another option, how to conduct external insulation, having poured all the supports for the bath with expanded clay along the perimeter: after all concrete work, develop sinuses around each concrete base and pour out the expanded clay pillow. Such insulation will require additional costs for the development of soil and arrangement of waterproofing.

Foundation for heavy materials from expanded clay concrete blocks and foam blocks

A reliable foundation for an ordinary bathhouse with your own hands can only be done if you do not violate the basic construction technologies. Frame connected prepare concrete. Materials are calculated as follows: for the total cubic capacity of the foundation, take the ratio of materials: 12% cement, 25% sand, 45% crushed stone, the rest is water and clay. For expanded clay concrete compositions, the filler (crushed stone) is divided equally with expanded clay.

The composition will be warm, but requires the use of waterproofing materials without fail. Before building the foundation for the bath, from such a material, calculate the weight of the entire structure. It is suitable for lightweight construction from foam blocks, and for expanded clay concrete materials it needs to be strengthened. It is necessary to change the depth of the foundation laying, pour it deeper by 0.5 meters, this applies to each monolithic pillar.

DIY masonry blocks

The foundation in this case consists of expanded clay concrete blocks standing on concrete posts. To begin, mark the directions under the blocks, scoring 4 pegs on the outer perimeter of the future bath. Pull and level the cord to the height of about the first block. If you made base formwork when pouring concrete, the masonry is carried out according to its size, laying blocks on concrete pillows.

Lay in two blocks, filling the seam with mortar. Lay the next row perpendicularly, the edge of the expanded clay block or foam block should touch the cord. Blocks are mainly used in order to raise the height of concrete bases above the ground or with a large slope of the site. Lay the required height and leave it - let it dry.During masonry, lay studs between the blocks for attaching the log house.

The construction of the supporting structure for light materials

The weight of foam blocks is small up to 24 kg, with dimensions of 200 x 300 x 600 mm, in contrast to expanded clay concrete. The calculation of the foundation slab is not carried out as under the pillar foundation. In this case, the entire structure will lie on the plate, transferring all the loads to the soil evenly, so it is stronger.

Building a slab (a slab version of the foundation) is easier to do than a pillar version, but it will also work for a building from a log house. Depth is not needed for a monolithic surface foundation with a height of 1-1.5 meters, there are enough recesses in the soil by 40-50 cm along the entire plane or perimeter, it depends on the configuration of the log house.

The height of the above-ground part of the concrete slab is 10-15 cm. When casting, a monolithic layer (slab) is obtained, bearing the entire log house, evenly distributing the load from the building to the ground. The slab version is suitable, both for medium-weight buildings, and for structures made of foam blocks, foam concrete blocks, it is possible to erect a sauna from sleepers, build a log house, there are many options for using slab technology, as much as is necessary for high-quality construction of buildings.

A slab foundation for the construction of walls from foam blocks is equipped as follows:

- Marking under the slab is carried out, the building is taken in width and length, but with a margin of 800-100 mm. It will be correct to lay only a stove around the perimeter under the bath, and inside, at the end, fill everything with clay.

- The soil is removed to a depth of 400 mm, the foundation pit is filled with sand, 200 mm thick. For foam blocks this pillow is enough. Now we seal it around the perimeter, there should not be any gaps. Although the log house is not heavy, the slab should work along the entire plane, the depth here is not as important as the uniform compaction of soil and sand.

- Now they put formwork around the future foundation, the height of the board is selected along the protruding part, in this case 150 mm.

- They knit cards from 12mm reinforcement, with a cell of 300x300, lay on the prepared site, after having previously placed the distances from plastic, or by spilling small nickels from the solution. After reinforcing, you can fill the solution. Such a foundation will not dry for long, 7-12 days.

Tip: In the summer, the sand dries quickly, moisten it with water before pouring concrete.

Tire foundation

A unique and at the same time strong foundation with your own hands can be built from car tires. This is an economical version of the base for a wooden structure made of logs or sleepers. The method of bookmarking the elements is as follows: marking is made for the outline of the bath. Then the top layer of the earth is removed, along the entire perimeter, 15 cm deep and 50 cm wide. The space is covered with rubble and sand mixed in a ratio of 1: 1. The pillow is rammed under the tires by hand tamper.

The required number of tires about 20-25 pieces of the same size and height is prepared (it all depends on the size of the tires and the bath). The perimeter of the tires is laid out so that they lie tightly to each other.

Now insert the threaded rods, tie them to the fittings threaded through the tires. We will fasten the supporting structure from them to sleepers, timber. The depth of the studs should be the entire thickness of the tires. The height of such anchors should be at least 250 mm so that the supporting beam for the log house or sleepers can be screwed on.

It is advisable to throw reinforcement around the entire perimeter and diagonally, and then fill the tire space itself. Reinforcement can be carried out directly through the body of tires, by drilling holes and threading reinforcement across the entire perimeter, so there is no need to conduct strapping from the outside with a channel or a corner.

You can make a set of blocks of tires and bury them directly in the ground. At the same time, the construction price will noticeably decrease; there is no need to pour a large slab for building a building from foam blocks or expanded clay concrete blocks.The device of load-bearing elements from tires is one of the cheap and simple options, which is not inferior in quality to the slab. This is an ideal foundation for a bath of timber, sleepers or for a solid wooden house (log house).

You can use the block version of the foundation of tires, where the marking is carried out in the same way as in other cases, but you do not need any pipes, piles, concrete blocks, and spend expensive reinforcement.

A set of tires (4−5 pcs.), Set on top of each other, will serve as a support for the log house or sleepers, instead of pipes and formwork. The terms of erection of such supports are minimal, the foundation of the tires dries quickly, since there is no large volume of concrete in the ground and after a couple of days you can carry out further installation of the frame bath or the installation of a wooden log house.

Repair wooden base

Sometimes the foundation for the bath is prepared from a thick beam, concreted directly into the ground, and sometimes a monolithic version is equipped. You need to know some little things before you properly repair the foundation of the bathhouse or build a new foundation under the bathhouse with your own hands:

- For example, a wooden structure made of sleepers or a log house is pulled together outside by brackets in the places of their subsidence. How to pull up the blockhouse, how many braces you need, you can calculate. With other foundations a little more complicated. You need to know how much the concrete dries, and only then mount the blockhouse or beams. If the bearing blocks burst during installation and their height is small, it is possible to pour a reinforcing layer of concrete around the blocks, filling in with all the cracks formed in the column.

- Having decided to make the foundation of the bath yourself, you will not only save considerable money, but also get a good experience. It is not difficult to build a monolithic or any other foundation with your own hands, you just need to go through all the stages of construction in turn and not violate the technology.

- Make the right calculation, marking for construction, excavation, reinforcement, insulation. Do all the necessary waterproofing work. Consultation with builders (developers) who build this type of foundation for a long time and have good experience will not be out of place.

Make a decision, from what material to build the foundation, from a log house, sleepers, what will be the height of the building, how many sleepers or timber. Whether a monolithic or concrete foundation is needed for a log house, wooden from sleepers or a solid foundation for a construction from foam blocks.

Knowing how to make a foundation for a bath is not all, preliminary calculations need to be done, and only then can it be started with confidence. Which foundation is better for the bath is up to you to decide, but how much materials will be needed to calculate it in advance and draw its structure. After a simple calculation, you can do everything perfectly, because heavy equipment is not needed here, except for a concrete mixer with a wooden gutter and a drain for concrete.

The foundation for a 3x5 bathhouse with your own hands: step-by-step instructions

Russian real bath - what could be better for the body and for the soul? There is no person who would be indifferent to her.  However, for each of us it is something special: relax, get together in a friendly friendly company, warm ourselves with a broom, etc.

However, for each of us it is something special: relax, get together in a friendly friendly company, warm ourselves with a broom, etc.

At the same time, the builder may even be one who has not previously been engaged in activities of this kind, since the procedure is very simple. There is a lot of useful information on the World Wide Web with which you can perform the task technically correctly. Let’s take a look at how to do the foundation for a 3x5 bathhouse with your own hands.

Choose a plot

A huge role in the construction is played by the choice of the site. This stage must be approached responsibly, since the life of the object will largely depend on what surface it is on.

The plot should be relatively flat. There should not be any boulders, stumps and other things. You must also calculate its size in advance. As for our case, we adhere to the size of 3x5.But keep in mind, the bath itself should have 3x3 meters and 2x3 - a dressing room.

Consider possible landslides, subsidence, slope, etc. A sandy soil would be an ideal solution, as it does not sag, practically does not move, so a shallow foundation can be made.

If you are going to carry out construction on clay or chernozem soil, then do the depth no higher than the level of freezing of the soil. This is about twenty centimeters. Do not forget to lay a sand cushion, which can protect against movements that are observed during frost heaving.

It is good if the site has a slight slope, necessary for the drain of melt and rainwater. It can be in any direction, with the exception of only the north.

Preliminary work

Before starting work, it is recommended to level the site, removing the topsoil from it, using a long cord for this purpose. Make drawings and markup.

Important! Do not forget that the width of the foundation should be ten centimeters larger than the wall. Marking accuracy must be checked using a right triangle and level.

The base is also of great importance. However, given the fact that the structure is not heavy, you can do without a strip foundation, choosing in favor of small supports. In the corners, it is necessary to build boxes that are needed to fill the pillars.

You can do all the work yourself or use the help of specialists. Their prices are different and depend on the level of skill of the person, his work experience and labor assessment.

Construction of the bath

After the cement mixture has hardened, we lay out the roofing material (pieces fit), thanks to them, the moisture and moisture from the foundation on the walls of the building will be much less.

Building the foundations for a 3x5 bathhouse with our own hands, we lay out the basement row on the roofing material, using not pieces in length, but a solid bar, and in width - we use its pieces of the required length. Be sure to make cuts at the ends of the material. This is necessary for overlapping joints.

The subsequent rows need to be laid out without a dressing room. Then cut off the necessary pieces of the bars you used and carefully fill their ends. On each row we lay the tape necessary for wall insulation. If you don’t have jute, use moss.

We lay a solid bar through each three or four rows to prevent the wall from moving away. Then all the bars in the opening need to be cut. The last row, as well as the first, is laid out from a solid bar, supports are made.

Internal work

Before you begin the internal work, you need to decide exactly how you want it to look. Someone performs it in one single restrained style, while someone prefers a simpler solution, trying to save a little on this.

We collect the floor and ceiling from the board, which has a width of about forty millimeters. It should be borne in mind the fact that the floors must be done regardless of the walls of the building.

[content-egg module = GdeSlon template = compare]

Formwork installation and solution preparation

Formwork is a frame made of boards and beams that will become holding walls for the foundation. Boards must be tightly fitted to each other to avoid leakage of the poured solution. When installing, the formwork must be cleaned and moistened with water. The solution inside the formwork is poured in layers of 15 cm, each of which is rammed and leveled. Concrete mortar pouring should be carried out in hot sunny weather, avoiding rain and damp.

In the preparation of the solution, the quality of the constituent components is very important. Sand and gravel should be dried and cleaned of earth, clay and debris. Do not save on cement quality! The ratio of components in the solution should be 6 parts of gravel to 4 parts of sand, the amount of water - not higher than 75% by weight of cement.

The mixture is prepared in the following sequence:

For extra strength, it is recommended to install a frame made of reinforcing bars laid along and across.

Building the foundation of the slab type

For a slab foundation, first of all, it is necessary to create a slab of reinforced concrete with a thickness of about 30 cm, corresponding to the perimeter of the bathhouse under construction.

In case the clay soil is on the site, it should be fixed with sand and gravel. To do this, marking the perimeter of the future building, dig a pit 1.5 m deep, extract clay and fill the place with gravel or sand, carefully tamping the material. If the soil is sandy, then it is enough to remove only the topsoil and replace it with sand. Level the surface with a level - there should be no slopes. Mark the future construction, strictly adhering to the perpendicularity of the sides.

The next step is the installation of formwork. Since you are making a monolithic slab, the requirements for the rigidity of the formwork design will be higher than when installing a strip foundation, since the load is much higher. Therefore, during installation, it will not be superfluous to use additional supports.

Stage Three: Waterproofing. As such, it is convenient to use a dense plastic film. Before laying it, it is necessary to provide surfaces with sufficient density. To do this, sprinkle cement on the sand inside the formwork at the rate of 50 kg per 10 square meters, mix thoroughly with a rake to a shallow depth (4 cm will be enough) and pour over water. After hardening, put the film.

Next, prepare the fittings. A suitable option for strength and weight would be bars with a diameter of 14 mm. The length of the valve must be shorter than the installation site by 10 cm: this will protect the rods from contact with the environment and corrosion. The fittings should be laid with a lattice, providing a cage of 15-20 cm in size, and twisted with a steel wire with a diameter of about 2 mm, or nylon ties. There should be two such grids, one above the other. Leave a distance of 20 cm between the lower and upper, while lowering the lower one above the waterproofing layer by 5 cm. During concreting, the upper grille should be recessed by 5 cm. Accordingly, the height of the slab will be 30 cm.

Practical advice to topics. who wants to build a bath with their own hands: what type of foundation to choose based on the type of soil on the site, how to properly build the foundation.

DIY foundation for a bath: Step-by-step instructions

To build a bathhouse is the first desire of most owners of private houses. But before construction, questions arise: from what material to build, what foundation should be made, etc. If you decide to mount the foundation for the bath yourself, this article will become an assistant and tell you in detail how to do it right.

Types of foundations under the bath

The bathhouse is a lightweight design, but there are two-story buildings, you need to choose the foundation individually for each building, starting from the indicators:

- Massive bath

- The specifics of surveying in the construction area.

- The material from which the bath will be collected.

- Monolithic. This is mounted on floating soil with high-lying hot water (groundwater).

- Column or pile screw. It is used for wooden baths made of timber or logs suitable for sandy soil.

- Tape. The most common option, used on soil with a deep bed of GW.

- Mixed type (tape + pile). They are rarely used for baths, suitable for soils with quicksand, high bedding.

Depending on the material used, the foundation of the bathhouse may consist of:

- made of brick

- concrete

- from blocks

- jellied or screw piles.

The foundation for the bath is in most cases lightweight, then the installation is done by hand.Of course, there are companies engaged in the construction of turnkey baths at a price of 10,000 m2, but in order to save money, it is easier to do the work yourself. How to make a foundation for a bath of various types, we will talk below.

The foundation for the bath is in most cases lightweight, then the installation is done by hand.Of course, there are companies engaged in the construction of turnkey baths at a price of 10,000 m2, but in order to save money, it is easier to do the work yourself. How to make a foundation for a bath of various types, we will talk below.

DIY installation of the base under the bath

Each of the listed types of foundation for a bath has its own characteristics, they need to be considered separately. The only thing that unites the work is the choice of a place for construction, the preparation of a project plan.

How to choose the right place for a bath bookmark

The choice of place for the construction of the bath should be taken seriously. The design is not built for one year, it should be located correctly. There are several types of location of the bathhouse: an extension to the main house, a separate bathhouse. If the bathhouse is an extension to a residential building, the foundation to it is carried out similarly to the main one with reference. Do not make screw piles when the main house is on a strip foundation.

A freestanding bathhouse means choosing a place away from trees and other plantings. The bath will be heated, smoke, sparks are not useful to fruit trees.

Why is a project needed?

Why is a project needed?

Do-it-yourself bath construction requires prior planning. Regardless of whether the building will be registered in the future or not. The easiest way to use a standard project, there are many of them can be found on the network. Photos are attached to any of the standard projects. Photos are needed to understand and present the construction in more detail.

Planning also includes an estimate where all costs and necessary material are calculated in order to start building the foundation under the bathhouse with your own hands.

Installation of a strip foundation

The strip foundation for the construction of a bath with your own hands can be done in several ways. The future platform is preliminarily marked on the site, a trench is dug through it to a depth of more than 50 cm, 4-5 cm wider than the expected masonry of brick or timber. It is better to dig a trench in summer when groundwater has the lowest occurrence level. The progress of subsequent work depends on the option selected:

The strip foundation for the construction of a bath with your own hands can be done in several ways. The future platform is preliminarily marked on the site, a trench is dug through it to a depth of more than 50 cm, 4-5 cm wider than the expected masonry of brick or timber. It is better to dig a trench in summer when groundwater has the lowest occurrence level. The progress of subsequent work depends on the option selected:

- A pillow is made of gravel and coarse sand. Each layer is rammed, should have a thickness of 15 cm. You can use the finished mixture of ASG, but it costs more. For better compaction, sand is recommended to be shed with water. A liquid cement mortar is made (it should resemble sour cream), spilled on a sand pad. A brick or rubble stone is mounted on the base. It will be a brick base mounted with a brick. Between every second row, a masonry net is laid. Waterproofing roofing material (2 layers).

- Another way starts with filling the pillow from ASG to half, rammed in exactly the same way as in the first case. It is important that the surface of the pillow is aligned. The next step is laid in one row brick. After they mount the formwork from boards and timber 40x40 mm. The height of the formwork is more than 40 cm. Concrete based on moisture-resistant cement is poured into it.

- The method is used for dense soil. The formwork is installed from a dense material and timber, for example slate. Lay slate sheets need overlapping 8-10 cm for tight formwork. Sand is poured into the formwork, which is tamped. The next layer is covered with gravel on a half-dug trench. The seal design is flooded. After they begin to pour concrete. The concrete layer should be no more than 150 mm. Concrete should be poured before the appearance of a cement slurry on the surface.

For uniform drying, the foundation is covered with sawdust, burlap on top, even a PVC film is suitable. Once in essence, the structure is unwound and watered again with water. So, it should stand under isolation for three days. Then the foundation under the bathhouse is opened, it is allowed to dry completely, settle down. The minimum drying period is 2-3 days. After it can be covered with waterproofing, for example, roofing material in two layers.

For uniform drying, the foundation is covered with sawdust, burlap on top, even a PVC film is suitable. Once in essence, the structure is unwound and watered again with water. So, it should stand under isolation for three days. Then the foundation under the bathhouse is opened, it is allowed to dry completely, settle down. The minimum drying period is 2-3 days. After it can be covered with waterproofing, for example, roofing material in two layers.

For the construction of the foundation for a strip-type bathhouse, several factors must be taken into account:

- The height of the fill above the ground should be 20–40 cm. It depends on the level of HS and the material from which the walls are assembled, so for a bath from a beam, the height of the base should be greater, since the tree does not like moisture.

- Silicate brick is not suitable for the construction of the foundation, over time it is destroyed by moisture. Red ceramic is made at high temperatures and humidity is not afraid of him.

- The tape has a width of 25-50 cm and depends on the material from which they will build a bath.

- Concrete can be purchased ready-made, but it will be cheaper to make it yourself.

- sand (preferably coarse-grained, it is pre-cleaned) 5% moisture - 1150 kg,

- Portland cement (moisture resistant) - 400-500 kg,

- crushed stone (small or medium) - 1800-200 kg,

- water - 170-175 l

You can also calculate the amount of concrete on the foundation of the bath yourself. For example, a strip foundation with a height of 0.3 m and a length of 19 m contains 0.3x0.3x19 = 1.71 m3. Similarly, you can calculate any volume. But it is necessary to additionally take into account that a foundation is also needed for the stove, therefore, a supply of 0.3 m3 must be added to the resulting volume.

Installation of the column foundation

The simplest type of foundation for a bath of timber, chopped or logs. A good option for any type of soil, especially in hilly areas.

The simplest type of foundation for a bath of timber, chopped or logs. A good option for any type of soil, especially in hilly areas.

The design consists of pillars, which are located at the corners of the future bath, under all the bearing walls. The distance between the posts is a maximum of 2 m.

It is not difficult to make a column foundation with your own hands, you can use it:

- wooden or metal, asbestos pillars,

- brick posts laid out,

- flooded piles

- screw posts.

An inexpensive option is wooden poles, but they must be dried and treated with tar or an antiseptic of deep penetration, such as Senezh, before use. For a columnar foundation made of wood, it is better to use larch or aspen, as these wood species are not afraid of water and get wet, they only become stronger. Set in pre-drilled holes where sand or ASG is poured, fixed with concrete pouring.

Brick columns are the most time-consuming type of foundation with your own hands for a bath. But making an effort with this work can be done. A similar circuit can be seen in the figure.

Brick columns are the most time-consuming type of foundation with your own hands for a bath. But making an effort with this work can be done. A similar circuit can be seen in the figure.

The location of the posts is marked, the top layer of soil is removed and a hole is dug, 10-20 cm wider than the future pillars in diameter. A sand cushion of at least 15 cm is laid. A column of bricks in two rows is mounted on top.

Do-it-yourself concrete piles are mounted most often, since the work, although laborious, does not require special skill. Drill wells with a depth of at least 1.5 m and a diameter of at least 250 mm. In the holes lay the connected frames from the reinforcement. They are knitted in advance from reinforced rods of 3 pieces, short connecting and knitting wires. The structure is poured with concrete. A brick column is laid on top of the pile.

You can simplify this design by taking an asbestos pipe with a cross section of 200 mm and install them in the wells. Concrete is poured into the pipe. The gap between the pipe wall and the well is filled with clay or gravel and rammed.

Concrete should be poured into the pipe gradually. The first time the filling is carried out at ⅓, since after that the pipes will slightly raise. The second stage is filled with another ⅓ part and the iron reinforcement is inserted inside. Only after that the rest is poured. Such a foundation dries completely in 5-7 days.

Another option for pillars is screw piles. They are sold prefabricated and have blades. They are screwed into the ground with the help of a bar. The only negative is that it is impossible to do the work alone with your own hands. It can be screwed to various depths, which is good for uneven surfaces.

Installation of a monolithic foundation under the bath

The type of foundation is used for any soil, but most often if there is a swimmer.The design is expensive, but the pressure on the soil is evenly distributed and the bath does not warp over time. There is no need to install a separate pillow and foundation under the stove. The structure is either poured with concrete on a mounted frame made of reinforcement, or ready-made reinforced concrete slabs are used.

The type of foundation is used for any soil, but most often if there is a swimmer.The design is expensive, but the pressure on the soil is evenly distributed and the bath does not warp over time. There is no need to install a separate pillow and foundation under the stove. The structure is either poured with concrete on a mounted frame made of reinforcement, or ready-made reinforced concrete slabs are used.

Do-it-yourself installation of a monolithic foundation for a bathhouse is carried out in stages:

- Digging a trench to the width of the foundation and a depth of 80-60 cm.

- A pillow of sand and gravel 15 cm is poured at the bottom.

- Waterproofing, for example, roofing material is reinforced. Layers can be 2-3, the main thing is that there are no open areas, overlapping 10-15 cm.

- Then the formwork and reinforced encircling are done, which are again poured with concrete.

- It is important to think about where to drain and install the pipe after solidification before pouring, it will be more difficult to do this.

Only the owner can choose the right foundation option. It is necessary to build on this moment from one's strengths and material capabilities.

[content-egg module = GdeSlon template = compare]

Do-it-yourself ribbon foundation for a bath, step by step instructions

An integral part of any building, including a bath, is the foundation. The principle of pouring the foundation is no different from laying the foundation for a residential building. The category of the foundation for the bath is determined based on the following factors:

An integral part of any building, including a bath, is the foundation. The principle of pouring the foundation is no different from laying the foundation for a residential building. The category of the foundation for the bath is determined based on the following factors:

- The load on the land. In most cases, the bathhouse is an oversized building. Naturally, the load from its design will be less, and this means that there is no need to lay too massive a foundation.

- Features of the soil. The soil beneath the building may be heaving, or slightly foul. The groundwater level may be deep, or lie close to the surface of the ground. The soil is sandy, clayey, chernozem, and so on. Each of them contributes to a certain coefficient of shrinkage of the building. This should be taken into account when determining which foundation to fill.

Before you familiarize yourself with the step-by-step instructions for filling the foundation for a bath with your own hands, you need to consider the features of the main types of substrates that are used in this case.

Phased work

It was time to do the foundation work under the bathhouse with your own hands. Step-by-step instructions describe the following work:

- Choice of a place for filling.

- Site preparation.

- Digging a trench.

- Concrete works.

Before starting the preparatory work, it is necessary to have on hand a project for the future bath. This is necessary in order to accurately determine what size the foundation should be, even if all the work will be done on their own (without using the services of the construction team).

The bathhouse can be a separate one, or an extension to the main building. Wooden arbors cannot be placed near it (a spark can cause them to ignite). The building should stand at a distance from fruit trees (smoke will harm their branches, foliage and fruits). Compliance with this rule ensures fire safety during the operation of the building.

If the building design allows you to build it near the house, then the foundations of both buildings should be identical. In the case of a separate bath, its foundation can be of any structure (tape, slab, etc.).

The next stage is the preparation of the site for earthworks. If a tree grew in the place where the building will be located, be sure to remove the entire root system so that it does not grow inside the building, or does not destroy its base. Useful soil can be removed beforehand. It can be used for backfilling in flower beds, or for planning lawns. During concrete work, cement slurry can damage the fertile soil layer. Therefore, they should be carried out as close as possible to the building itself (ideally, inside the future room).

Earthwork is a very important preparatory process before filling the foundation with your own hands. At this stage, it is necessary to know the depth and width of the future foundation.In most cases, a shallow tape monolith is sufficient.

Foundation trench

Foundation trench

The walls of the trench will serve as the formwork. Therefore, they should be as even as possible (in order to avoid overspending of the material). During the execution of the work, the land can be thrown inside the future building. This will make it easier to level and level the floor. One of the most important elements of the foundation of any building is bedding. Sand is mainly used for this.

It should be well compacted (by a vibrating plate, or a vibro-paw). If the terrain is characterized by a high level of groundwater, then at this stage it is necessary to take care of waterproofing. In the old days, under the tape foundations, a layer of clay was poured and strongly compacted. Then a small layer of liquid clay was poured. After she stood, they carried out concrete work. This is the cheapest waterproofing option. But today, inexpensive materials are on sale that are ideal for protecting the base of a building from groundwater.

The final stage of the preparatory work is the installation of formwork for the strip foundation, or basement. For convenience in pouring the monolith, its height should correspond to the level of the future foundation for the bath.

Each type of foundation requires its own procedures. Therefore, further in a step-by-step instruction for pouring the foundation of the bathhouse, each type of foundation will be described separately with its own hands.

The concrete grade for such work should be no less than M200 (220 liters of water, 324 kilograms of cement grade 400/500, 1296 kg. Sand, and 1296 kilograms of crushed stone of fraction 10 are taken per cubic meter of the mixture). It is imperative to reinforce the monolith layer so that it is stronger. For this, fittings with a diameter of one centimeter are enough.

The strip foundation is used on dense ground. If the earth is not prone to heaving, such a foundation will be enough to withstand the construction of the building. Choosing this method, you need to consider that its use is permissible only on relatively flat areas. The depth of the trench should be 20, 40, or 60 centimeters. You can dig it out yourself without using an excavator. At the bottom of the trench, a bed of sand is made, compacted. Its thickness is 20 centimeters.

Then the frame of the reinforcement is connected. It must be placed on small stones so that after pouring it is completely in the monolith. After the waterproofing has been laid, the armored belt and formwork are mounted, concrete can be poured. To do the work yourself, the mortar is prepared in the following proportion: two buckets of sand are taken on a bucket of cement, and three buckets of gravel.

The tape version must be firmly tied with rods. At the corners, a piece of reinforcement should be bent in half, and not bandaged with another rod. The strength of the monolith will depend on this.

Unlike tape monolith, this type of base is easier to do with your own hands. For this, during the preparatory phase, a shallow trench breaks out (this will be the bottom of the basement). Then a 1.3 meter deep well is drilled. At its bottom, sand is poured (thickness 30 centimeters), and compacted. After that, the frame from the reinforcement is connected, and placed in the well.

Do not immediately fill the entire cavity of the well, otherwise voids will form in the concrete at this depth. To avoid such difficulties, concrete should be poured gradually followed by compaction with a vibrating finger. This support should be left to harden for about a week. After this, the columns can be connected to each other, installing bars, or channels. If the support is unevenly poured, you must not try to pull it out so that it can be installed correctly later. To align the support, it is necessary to cut off the upper part of the column, bringing it under the level.

Such a base for a bath is used in the case of a high level of groundwater, or in the presence of floaters. During the preparatory work, the entire area where the building will stand is cleared.The thickness of the soil corresponding to the thickness of the monolithic slab is removed. At the bottom of the trough, sand is poured and compacted. Then the waterproofing film is lined.

After that, the frame of the reinforcement is connected. To make it easier to do this work with your own hands, at first two nets are knitted with a cell of 30-40 centimeters. The first is placed on supports (so that it does not lie on the sand) at the bottom of the pit. The second grid is mounted above it at a distance of 15 centimeters using reinforcing bars. Fix these elements with a flexible knitting wire. Watch the video how to make a slab foundation for a bathhouse.

After performing such work, the entire plane is poured with concrete. A feature of such a foundation is that the weight of the building is distributed over the entire land. Therefore, it does not sag, even if the bath is built on unsteady soils.

Regardless of the type of foundation, whether tape, slab or any other - before pouring the monolith across the structure, you need to place a plastic pipe filled with sand. This mortgage will allow to bring sanitary communications into the building of the bathhouse.

[content-egg module = GdeSlon template = compare]

Preparing for the construction of the bath

Before the time when the bath will be suitable for use, a lot of time will pass. The most time-consuming is the foundation stage. It takes from 3 months to a year.

The main stages of construction:

- Development of a drawing of the structure and layout on the site.

- Procurement of materials and preparation of tools.

- Foundation construction.

- The construction of walls, the installation of windows, doors, stoves.

- Roofing.

- Interior decoration of the bath.

The foundation, as the basis of the future construction, requires a responsible approach to the selection of the site, materials and quality of construction work.

What type of foundation to choose